Vertical Roller Mill Grinding

.jpg)

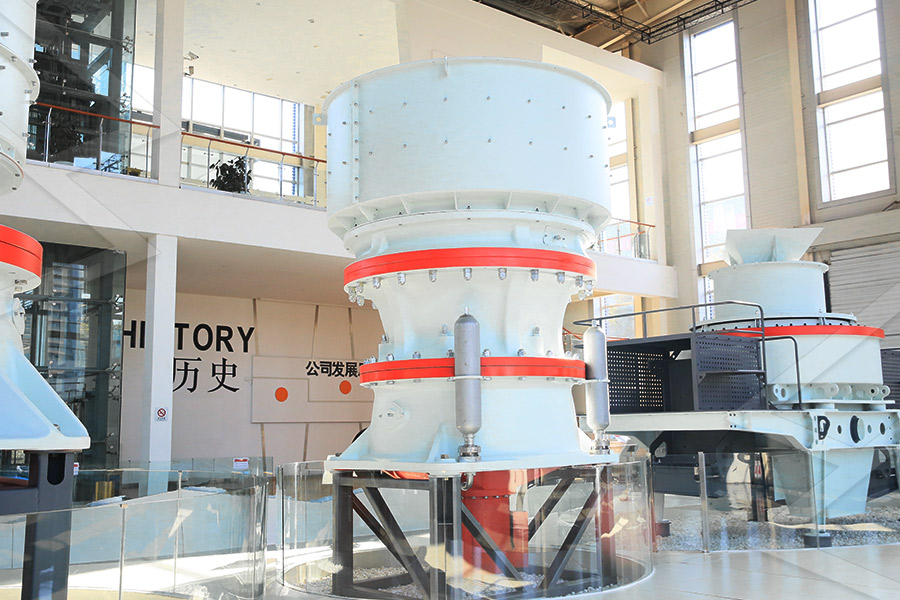

Vertical roller mills FLSmidth Cement

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It 2022年5月31日 The vertical roller mill (VRM), including powder separation and crushing subsystems, is used extensively for intermediate crushing of minerals in several industries such Analysis of vertical roller mill performance with changes in 2009年1月1日 Based on screening analysis, laser size analysis, grindability and rigidity tests of samples collected on line from a cement and a power plant, a simulation of the grinding Grinding process within vertical roller mills: experiment and 2017年10月27日 The VRM is a type of grinding mill integrated with multi functions such as grinding, drying and separation, used for grinding of coal, petroleum coke and minerals Most PROCESS CONTROL FOR CEMENT GRINDING IN

(PDF) Performance Evaluation of Vertical Roller Mill in Cement Grinding

2017年9月11日 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the 2022年4月4日 The quadropol® vertical roller mill by thyssenkrupp Industrial Solutions takes a holistic approach to modern grinding systems in terms of its simple and compatible design VERTICAL ROLLER MILLS A holistic VRM approach2023年7月4日 The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy Roller Mill Springer3 天之前 Vertical Roller Mills (VRM) have a clearly higher energy eficiency than ball mills, even if the ball mill is combined with a roller press This and further arguments led to the increased SikaGrind® for vertical roller mills

Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill

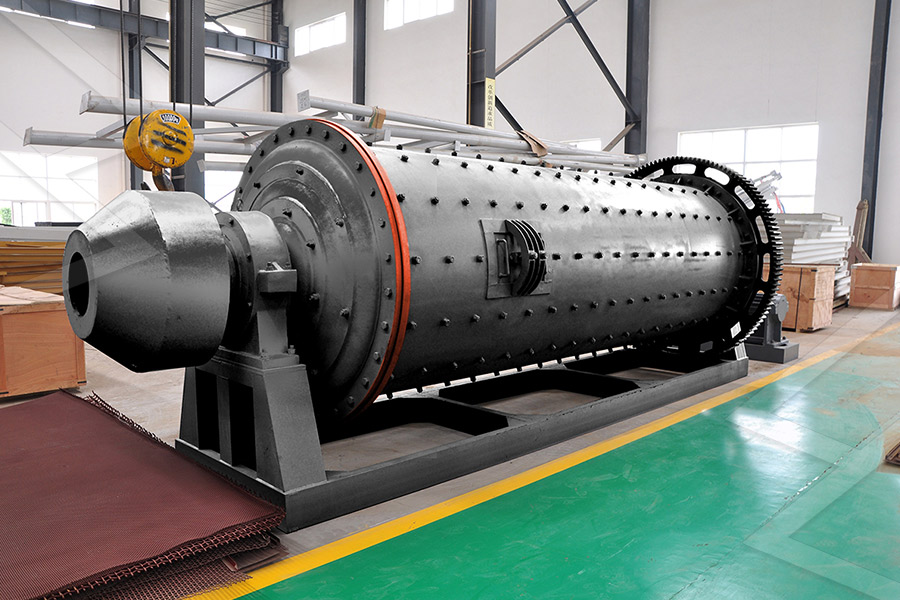

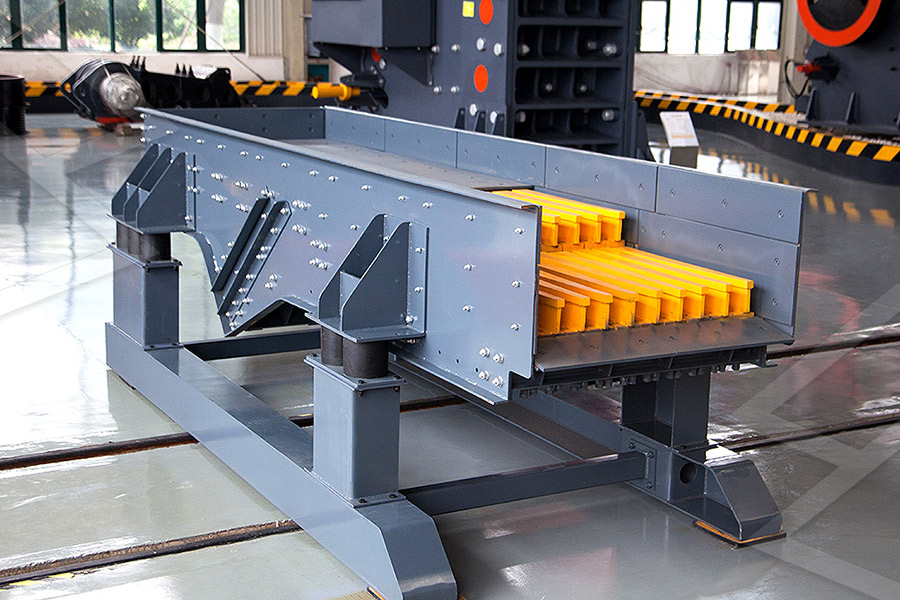

Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill; Fine Grinding Mill (Centrifugal Roller Mill) Kurimoto Roller Mill; Batch Type Highspeed Planetary Mill Kurimoto High G; Horizontal Grinding Mill Overflow Type, Gratedischarge Type, and Compartment Type Ball Mill; Horizontal Coarse Grinding Mill Rod MillThe higher the demands placed on the quality of ground material, and the lower the desired energy consumption of the overall grinding system, the more important is the efficiency of the separator The sepol® high efficiency Grinding technology thyssenkrupp Polysius2023年10月3日 Grinding Rollers: Grinding roller is the main part for crushing and grinding materials The grinding roller is composed of cast steel roller sleeve, forging shaft and wearresistant surfacing bushing The grinding roller is installed on the rocker arm of the cement vertical roller mill, under the action of external force, it is pressed tightly on the material of the grinding What is a vertical roller mill (VRM)? A Comprehensive Guide 2023年12月4日 A vertical roller mill (VRM) is a grinding equipment used for the size reduction of minerals, cement, and ceramics The capacity of the VRM depends not only on the grinding material properties but also on the operational parameters of the VRM This study investigatedNumerical Investigation of Vertical Roller Mill Operation

Vertical roller mills: The new leader in grinding technology

2019年10月11日 The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the verticalrollermill (VRM) For now, the HPGR has already presented in a noteworthy number of mining projects whereas VRM technology, a new entrant, is still not fully acceptedSAG Mill; Roller presses Roller presses High pressure grinding roll (HPGR) KREBS® vMAX™ Vertical Slurry Pump ODS Diaphragm Pumps Back Slurry Valves KREBS® T2 Check Valve PERI™ AutoCharge Mill Grinding Ball Charging System Back PERI™ Online Slurry Analysis System Back Transfer Point Alignment AutomationPremium solutions for the cement industry FLSmidth2024年9月15日 Grinding is a basic process widely encountered in mining, metallurgy, and chemical industries To adapt to different working conditions, various types of grinding equipment have been designed, such as roller press, horomill, ball mill, and vertical roller mill (VRM)Numerical investigation of a vertical roller mill using DEM 2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and table) The vertical roller mill has the advantages of low energy consumption, high output, easy maintenance, etc, and has been widely applied Roller Mill SpringerLink

.jpg)

Vertical Roller Mills used for the comminution of mineral

2024年5月24日 energyefficient size reduction compared to tumbling mills Figure 1: Vertical roller mill operating principle (left: standard configuration, right: configuration with grit extraction) Pilot plant description and standard testing methods The grindability of a particular mill feed forms the basis for the design of an industrial grinding plantOur bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeOK™ Raw and Cement Mill FLSmidth CementThe vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement Vertical Roller Mill Operation in Cement Plant2013年3月13日 using Cement Vertical Roller Mill as the Finish Grinding of Cement Industry” was passed the technical appraisement by China Building Material Association; Year of 2011, the initial TRMK5041 Cement Vertical Roller Mill was operated in Kashi Tianshan Cement TRM SERIES CEMENT VERTICAL ROLLER MILL TRM

(PDF) LEARNING FROM OTHER INDUSTRIES;

2019年4月16日 The vertical roller mill (VRM) is a comminution device in which crushing, grinding and classification processes are combine together into a single unit operation2015年8月31日 With the market demand for efficient, highly flexible, and highcapacity plants for cement production, it was time to develop an innovative drive concept to cope with the demand: the world's first vertical roller mill (VRM) with driven rollers With this concept, it is the rollers of the VRM that are driven, notas is usually the casethe grinding table With the rollerdriven Introducing the Vertical Roller Mill with Driven Rollers: An Vertical roller mills have numerous applications in many different industriesAlthough they are widely used in the cement sector, for example, you are just as likely to find a vertical roller mill being used to handle ores in mining processing plantsThere again, vertical roller mills also have uses within the context of power stations where they are primarily used to pulverize coalVertical Roller Mill MagotteauxCLUM series ultrafine vertical roller millwas produced by Shanghai Clirik Machinery Co, Ltd Relying on 12 years of experience in the production of ultrafine powder and based on German and Taiwan ultrafine vertical mill technologies The top technical team members were joined this project Besides, highquality wearresistant parts are used to develop milling equipment which Ultra fine vertical roller millUltra Fine Millultramill

.jpg)

Vertical Roller Grinding Mill Machine CLIRIK Machinery

CLIRIK Machinery produces all kinds of vertical roller mills for ore powder making, such as Raymond roller mill, ultrafine grinding mill, ultrafine vertical roller mill, and so on Home; Calcite Vertical Roller Grinding Mill Customer Site Calcite Vertical Roller Grinding Mill Customer Site Tel: +86(021) +95 Fax: +86 Vertical Roller Mills; Vertical Roller Pregrinding Mills; Rubber and Tyre Machinery; TriLobe PD Blower; Transit Mixers and Bulkers; Services and Spare Parts; Contact Info Address: A1/1, MIDC, Butibori, Dist – Nagpur, Maharashtra, India – VRM – AMCL Machinery LimitedVertical roller mills are widely used in chemical, metallurgy, nonmetallic mining, and other industries It suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 7(the Moh’s hardness)Vertical Roller Mill SBM Ultrafine Powder Technology2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and

.jpg)

Limestone Powder Ultrafine Vertical Roller Mill

Disadvantage of limestone powder ultrafine vertical roller mill: 1 Limestone powder ultrafine vertical roller mill is not suitable for grinding hard and abrasive materials, with short service life and frequent maintenance Moreover, its wear parts are more expensive than ball mills, but compared with the total maintenance of the ball mills 2022年1月23日 Productivity increase of the vertical roller mill for cement grinding In Proceedings of the IEEE Cement Industry T echnical Conference, Hershey, P A, USA, 20–24 April 1997 10Analysis and Optimization of Grinding Performance of Vertical Roller 2022年4月4日 for the smooth running of the mill The roller units and mill housing are not connected, leaving the mill housing free of forces The mill foundation is designed according to the force transmission, which results in a vibration value due to the grinding process of less than 2mm/s, measured at the roller units Of course,VERTICAL ROLLER MILLS A holistic VRM approach2023年8月17日 The rollers The OK mill design uses the same swing lever and roller assemblies for either cement or raw applications It also allows the ability to continue using the unique grinding roller profile of the OK cement mill and an optimised spherical grinding profile for raw grinding applications The rollers are in a lifted position when the mill OK™ mill The most reliable and efficient mill for raw and

Vertical roller mill, Vertical roller grinding mill All industrial

vertical roller grinding mill GRMR vertical raw mill Output: 65 t/h 900 t/h Process introduction The GRMR raw material vertical mill of CHAENG is a kind of new high efficiency, energy saving and environment friendly grinding equipment specially for cement raw material grinding system2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on the energy Analysis and Optimization of Grinding Performance of Vertical Roller 2015年3月15日 The grinding parts of a Loesche mill (Fig 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring systemBetween the working surfaces of track and rollers, particle bed comminution takes place A dynamic air separator (3) is located above the grinding chamber, Research of iron ore grinding in a verticalrollermillA Vertical Roller Mill (VRM) is an advanced and efficient grinding machine commonly used in the cement industry for grinding raw materials and clinker VRMs have become increasingly popular due to their ability to produce finer products with lower energy consumption compared to traditional ball mills Advantages of Vertical Roller Mills:Vertical roller mill vs ball mill for cement grinding:

VRM In Cement Plant Maximize Energy Saving CNBM

Vertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as cement, electric power, metallurgy 2023年11月21日 In the present incident, one of the rollers of grinding mill in cement plant failed during operation, exhibiting longitudinal cracking over inner surface Deposition welding was carried out just before the incident to match the wornout profile of the roller Investigation revealed that the subsurface of the cracked region contained discontinuities like blow holes Operational Failure of Vertical Roller Attached to a Grinding Mill CLUM large ultrafine vertical mill is especially suitable for the production of filler in large paper mills and coating grade calcium carbonate It is suitable for largescale ultrafine powder processing enterprises The ultrafine powder products produced by this equipment are widely used in papermaking, plastics, rubber, PVC, wire and cable, artificial stone, paint and coatings CLUM Ultrafine Vertical Roller Mill2017年8月11日 slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the vertical2 µm 5 µm Loesche

Grinding Machine Manufacturer, Vertical Roller Mill, Grinding Mill

Grinding Machine, Grinding Mill, Vertical Roller Mill manufacturer / supplier in China, offering Jet Mill to Make Dry Mine Material Grinding, 325 Mesh Input Material Jet Mill Ultra Fine Grinding Machine, Super Fine Powder Steam Jet Mill Ultrafine Grinding and so on Contact Supplier 2021年9月1日 While the data were evaluated within the scope of energysize reduction relationship for vertical roller mills, Morrell’s equation (Morrell, 2004) was based on The K parameter for present data was back calculated and a preliminary energysize relationship was developed to predict the grinding energy of the vertical roller millPredicting the grinding energy of vrm depending on material Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal The coal mill utilises compression and shear force generated between the large rollers and the rotating table to crush and grind raw coal, removing the need for a separate piece of equipment for crushing The coal mill can also grind petroleum ATOX® Coal Mill FLSmidth CementVertical Roller Mills (VRM’s) for a wide range of applications with capabilities from as little as a few tonnes per hour up to 1500 tph The material to be ground is crushed between the rotating grinding track and the individually guided grinding rollers Grinding is carried out primarily through the application of compressive force Vertical Roller Mills Ammermann Pty Ltd

.jpg)

Study on Particle Characteristics of Cement by Vertical Roller Mill

2013年5月1日 According to the research on the fine grinding process of vertical roller mill to produce cement by Liu et al (2013), the particle size distribution can be more uniform than the average size on 2017年9月11日 Grinding and separation efficiency of vertical roller mill were evaluated In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were compared(PDF) Performance Evaluation of Vertical Roller Mill in Cement Grinding 2024年8月7日 In this contribution, a vertical roller mill (VRM) is modelled across domains Subsequently, selected simulation analyses are conducted and validated against measurement data from the physical demonstrator and analytical or empirical calculation models This mill uses conical grinding rollers, which are individually pressed onto a flat Multiphysics Simulation of a Vertical Roller Mill in Vertimillreg; is globally recognized as an energy efficient grinding machine Through a low total cost of ownership, they bring substantial improvement to the profitability of concentrators During the years, Vertimillreg; technology has proven to be efficient especially in Vertical mill Vertimill® 7000 Metso Corporation roller /