Crushing Equment BituminousCoal Sumatra

Porosity Changes in ThermallyTreated Bituminous Coal

2023年5月18日 through stepbystep crushing, this study investigated the pore structure of thermallytreated bituminous coal during crushing using lowfield nuclear magnetic 2022年10月1日 Coals from the Ombilin Basin are highvolatile bituminous C coals with mean random vitrinite reflectance values of 058%–066% Vitrinite content is the most dominant Petrological, mineralogical, and geochemical compositions of coal 2009年1月31日 Sample CQ01, a high volatile bituminous coal from Ombilin, is from a small basin in a tectonically active area in West Sumatra Some Ombilin coal has been affected by Geochemistry and petrology of selected coal samples from Sumatra crushing process to reduce the size of coal grains to facilitate the grinding process Milling and sifting aimed to obtain finer grain sizes; a coal mesh size of 200 was required for each sample 048 GIESED2 2019 IOPscience

Porosity Changes in ThermallyTreated Bituminous Coal

2023年3月27日 Based on the method of opening closed pores through stepbystep crushing, this study investigated the pore structure of thermallytreated bituminous coal during crushing 2024年2月23日 In this paper, microCT was used to perform CT scanning on two bituminous coal samples before and after 72 h of dissolution with different concentrations of acetic acid solution to quantitatively identify the changes in Porosity and Fracture Changes of Bituminous The main factor to determine coal qualities is the coal rank The coal rank from the lowest to the highest are lignite, subbituminous, bituminous, and anthracite The factors thatProximate, ultimate analysis, and calorific value of Indonesia 2009年1月31日 Bukit Asam (Persero) Tbk mining area is dominated by organic sulfur, especially subbituminous coal [Belkin, et al, 2009] The forms of organic sulfur, pyrite sulfur, and sulfate Geochemistry and petrology of selected coal samples from Sumatra

The effect of cutting speed on the generation of bituminous coal

Based on the deformation characteristics observed during the invasion process, the coal body can be further divided into three zones: I) Crushing zone: This zone extends from the origin to a South Sumatra (3801%), South Kalimantan (768%), and East Kalimantan (375%) [3] Bituminous and Subbituminous is the type of coal mostly produced in Indonesia [8] Coal is an alternative energy source that substitutes oil and gas which is economically valuable crushing process to reduce the size of coal grains to facilitate the 048 GIESED2 2019 IOPscience2023年9月1日 Effect of supercritical CO2 transient highpressure fracturing on bituminous coal microstructure September 2023; Energy 282(5–6):; gas impact crushing coal matrix is CO 2 Effect of supercritical CO2 transient highpressure fracturing 2020年5月14日 [Show full abstract] study, it was obtained: a mixture of coal with mangrove wood charcoal with the composition of 25% Sin coal + 75% MWC = 0067% sulfur content, 50% Sin coal + 50% MWC = 0089% (PDF) Coal quality characterization in East Kalimantan Province

.jpg)

Effect of supercritical CO2 transient highpressure fracturing

2023年11月1日 Carbon dioxide phase change fracturing is an effective permeability enhancement technology, and its influence mechanism on the coal microstructure remains to be further investigated To explore the impact of CO 2 fracturing on the coal chemical structure, the selfdeveloped transient highpressure fracturing of CO 2 test platform was independently 2022年8月10日 Characterization of bituminous coal is carried out to evaluate the behaviour of coal when it is subjected to different loading or stress conditions such as tensile stress, shear stress and normal stress Index properties such as microstructure of geomaterial, density, porosity, specific gravity, water absorption, colour and formation that form a set of intrinsic Experimental and numerical analysis of constitutive 2023年12月16日 Coal and gas outburst is a dynamic disaster that poses a significant threat to coal mines Energy analysis is an effective tool for understanding the mechanisms behind such outburst The energy sources and dissipation during outbursts were explored using a multifunctional test system, and the energy transformation relationship was analyzed based on Energy Evolution and Coal Crushing Mechanisms Involved in Coal 2023年3月27日 Based on the method of opening closed pores through stepbystep crushing, this study investigated the pore structure of thermallytreated bituminous coal during crushing using lowfield nuclear Porosity Changes in ThermallyTreated Bituminous Coal

Effect of moisture content on structural evolution characteristics

2019年4月1日 Subsequently, this technology (ie, crushing solid materials using electrical pulse) attracted the attention of researchers globally [17], [18] and that of SC bituminous coal samples with different moisture content is presented in Fig 6 It can be seen that the average breakdown field strength decreases with the increase of moisture 2020年8月1日 Bituminous coals are still the main source of energy in the world However, these brittle porous materials are prone to crushing under action of industrial toolsIndentation of bituminous coals: Fracture, crushing and dust Download Table Proximate, ultimate analysis, and calorific value of Indonesia coals from publication: Geochemistry and petrology of selected coal samples from Sumatra, Kalimantan, Sulawesi, and Proximate, ultimate analysis, and calorific value of Indonesia 2021年6月25日 from coal combustion are primarily sulfur dioxide (SO 2), with a much lower quantity of sulfur trioxide (SO 3) and gaseous sulfates These compounds form as the organic and pyritic sulfur in the coal are oxidized during the combustion process On average, about 95 percent of the sulfur present in bituminous coal will be emitted as gaseous SO x11 Bituminous And Subbituminous Coal Combustion

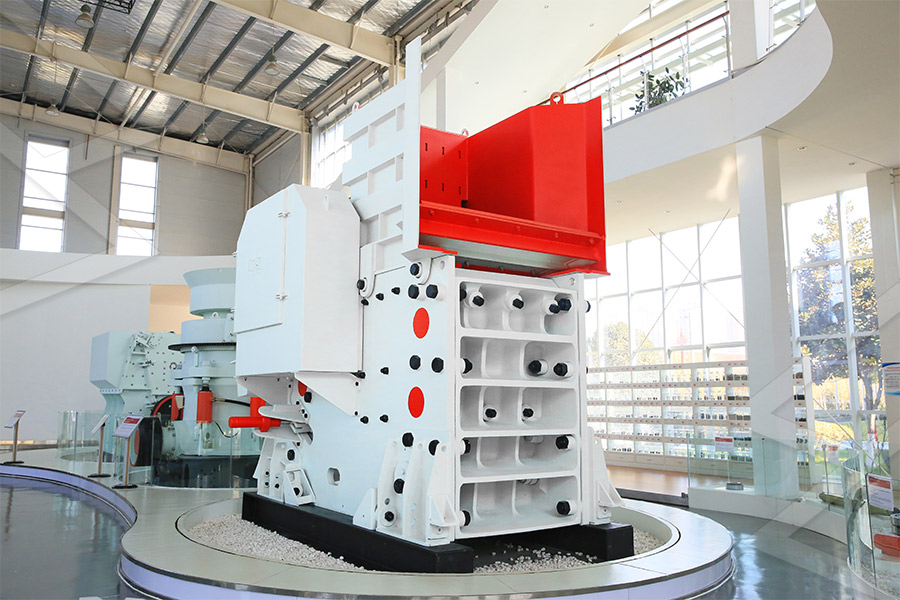

RMKO, Atlas to develop Sumatra coal crushing plant

Indonesian coal mining contractor RMKO has partnered with domestic producer Atlas Resources to develop a coal crushing plant and other supporting mining infrastructure in south Sumatra The crushing plant and other facilities are targeted for completion by the second half of this year, said RMKO, which is a subsidiary of coal logistics firm RMK2011年1月6日 steps: coal crushing, slurry dewatering, solid/liquid separation, oil recovery, and briquetting Fig 4 is a full view of a UBC plant The following outlines each step in the process 1) Coal crushing This step includes taking in raw coal, preliminarily roughcrushed to 50 mm or smaller in size, and crushing the raw coal to 5 mm orDemonstration of Upgraded Brown Coal (UBC Process 2018年4月3日 Laboratory and industrial research confirms that decrease in the clinkering properties of bituminous coal when it is present to excess in the coking batch improves the strength of blastfurnace coke If coal batch containing >70% bituminous coal is crushed until its content of the ≤3 mm class is 90%, the crushability Π25 may be increased by 18%, with Influence of the Crushing of Bituminous Batch on Coke Quality2023年3月28日 Porosity Changes in ThermallyTreated Bituminous Coal During StepbyStep Crushing: Implications for Closed Pore Variations with Temperature Natural Resources Research ( IF 54) Pub Date : , DOI: 101007/s11053023101944Porosity Changes in ThermallyTreated Bituminous Coal

Research on coal crushing behavior under supercritical CO

2024年3月1日 CO 2 fracturing enhances gas permeability by creating a complex network of fractures in coal seams Crushing serves as the foundation of fracture development, and studying the coal crushing behavior under supercritical CO 2 transient highpressure fracturing is of great significance to understand fracture evolution and guide precise fracturing This study utilized a 2009年1月31日 Coal mining in Indonesia has had a long history, beginning with the initial production in 1849 in the Mahakam coal field near Pengaron, East Kalimantan; in 1891 in the Ombilin area, Sumatra, (van Leeuwen, 1994); and in South Sumatra in 1919 at the Bukit Asam mine (Soehandojo, 1989)Total production from deposits in Sumatra and Kalimantan, from the Geochemistry and petrology of selected coal samples from Sumatra 2020年7月8日 The coal rank from the lowest to the highest are lignite, subbituminous, bituminous, and anthracite The factors that influencing of coal ranks are calorific value, volatile matter, moisture (PDF) The relationship between Indonesian coal qualities and This study is a petrographic analysis of the coal in the Bukit Asam Coalfield which includes a complex of working coal mines located near the small town of Tanjung Enim, South Sumatra, Indonesia The Bukit Asam coal seams are part of the Muara Enim Formation which is composed of shale, siltstone, claystone, sandstone and intercalated coal layers Within the immediate Organic petrology and geochemistry of Bukit Asam coal, South Sumatra

Study on coal pulverization characteristics and gas

2024年5月30日 The coal's particle size distribution properties after pulverization and the gas desorption behavior driven by pulverization are of profound meaning to the study of coal and gas outburst mechanism In this paper, based on the impact crushing experiment, the tectonic coal and primary coal are crushed under different impact energy conditions After screening the 2023年6月19日 Here, the biodegradation of bituminous coal and lignite to produce methane and the cultivation with inhibition of methanogenic activity by 2bromoethanesulfonate (BES) were performed to analyze the effect of biodegradation on coal pore development by determining the changes of the pore structure and the organics in culture solution and coal The effect of organics transformation and migration on pore 2021年8月11日 The chemical pretreatment of both types of coal led to enhanced yields of humic acid from 2115% to 578% for lignite lowrank coal and 116% to 496% bituminous high rank coal(PDF) Extraction and Chemical Characterization of Humic Acid 2009年1月31日 Geochemistry and petrology of selected coal samples from Sumatra, Kalimantan, Sulawesi, and Papua, Indonesia Tbk mining area is dominated by organic sulfur, especially subbituminous coal Geochemistry and petrology of selected coal samples from Sumatra

.jpg)

Porosity Changes in ThermallyTreated Bituminous Coal

2023年3月28日 Porosity Changes in ThermallyTreated Bituminous Coal During StepbyStep Crushing: Implications for Closed Pore Variations with Temperature Natural Resources Research ( IF 54) Pub Date : , DOI: 101007/s110530231019442021年6月1日 The essence of coal crushing process is the deformation of physical structure [8], [9] and the crushing process is closely related to the mechanical properties of raw coal [8], [10] These became more noticeable when the analysis was done for samples of the same type of coal rank, in this case, bituminous Mechanical and hydraulic Roles of moisture and cyclic loading in microstructures and 2020年11月1日 Bituminous coals are still the main source of energy in the world However, these brittle porous materials are prone to crushing under action of industrial tools Our early depthsensing nanoindentation tests of bituminous coals showed that even if the depth of indentation is within the nanoscale, these brittle coals are no longer continuous elastic media Indentation of bituminous coals: Fracture, crushing and dust 2024年11月1日 YJL bituminous coal and JS anthracite occurred depolymerization and decomposition reactions at 350 °C and 400 °C, respectively, producing and releasing a large amount of volatiles substances YJL bituminous coal releases more reducing gases, mainly including H 2, gaseous hydrocarbons and CO And below 820 °C, the mixture of YJL Utilization of low metamorphic degree bituminous coal in

Microstructure Evolution of Bituminous Coal Modified by

2023年3月24日 The microstructure of bituminous coal can be changed significantly due to injection of CO2 foam fracturing fluid into the coal seam, affecting CBM production efficiency To investigate the microstructural change characteristics of bituminous coal treated with highpressure CO2 foam fracturing fluid at different treatment times (0–24 h), mediumrank 2024年3月16日 1 The document analyzes the depositional environments and coal maceral contents between the South Sumatra and Jambi basins in Indonesia 2 The Jambi basin contains coal with high vitrinite and inertinite contents, indicating deposition in a backarc basin environment with fluvial to deltaic conditions 3 Coal seams in the South Sumatra basin Coals Petrographic Analysis and Depositional Environments 2023年10月8日 Coal is a sedimentary rock composed of plant organic matter and inorganic matter It includes crashing bituminous coal, smokeless coal, lignite coal and freezing coal Coal is softer and more easily broken than granite and basalt Cement clinker plants and power plants both use crushed coal or powder as the main fuel6 Types of Coal Crusher: Which Is Best for Crushing My Coal?2016年6月16日 The prediction results show that there is good performance for highvolatile and lowvolatile bituminous coals using the technique of crushing to 3 mm + densitybased separation while good separation performance of mediumvolatile bituminous could be achieved using a technique of 50 x 05 mm + densitybased separation, not necessarily crushingMaceral Liberation and Distribution of Bituminous Coal for

.jpg)

Study of synergistic behavior during bituminous coalcow

2024年7月28日 Cothermal chemical conversion of coal and biomass is one of the important ways to realize efficient and clean utilization of coal In this study, a typical Ningdong coalYangchangwan bituminous coal and cow manure were used to study the synergistic effect of intrinsic alkali, alkaline earth metals (AAEM) and organic matter on the cogasification of coal 2024年1月4日 Introduction The study employed novel nondestructive testing techniques for coal sample such as resonant column testing, cyclic torsional technique, and ultrasonic pulse velocity analysis Methodology The study confirms the coal in the present study as bituminous coal by analyzing the microstructure and composition of coal using scanning electron microscope and Evaluation of Material Damping Properties in Bituminous Coal2019年11月1日 Improving pore structures is key for enhancing coalbed methane (CBM) recovery The variations in pores of Chinese bituminous and anthracite coal were analysed by using lowpressure N 2 gas adsorption and CO 2 gas adsorption during 20 kHz and 50 kHz ultrasonic treatment Although the shape of the physisorption isotherm and hysteresis loop, Porosity changes in bituminous and anthracite coal with ultrasonic Request PDF On Mar 1, 2024, Yunzhuo Li and others published Research on coal crushing behavior under supercritical CO2 transient highpressure fracturing Find, read and cite all the research Research on coal crushing behavior under supercritical CO2

Porosity Changes in ThermallyTreated Bituminous Coal

Based on the method of opening closed pores through stepbystep crushing, this study investigated the pore structure of thermallytreated bituminous coal during crushing using lowfield nuclear magnetic resonance, lowtemperature nitrogen adsorption, and2024年5月1日 The resource characteristics of coalrich, oildeficient, and lowgas determines that coal will still occupy the dominant position of China's energy supply market for a long time, and the characteristics of high gas and low permeability of most coal seams lead to frequent coal mine gas disasters, which seriously threaten the safe production and Industry development Influence of plasma breakdown on pores and fractures in bituminous coal 2023年3月27日 Coal has many closed pores that limit fluid escape However, the evolution of these closed pores during pyrolysis has rarely been studied Based on the method of opening closed pores through stepbystep crushing, this study investigated the pore structure of thermallytreated bituminous coal during crushing using lowfield nuclear magnetic resonance, Porosity Changes in ThermallyTreated Bituminous Coal 2023年11月1日 Cao et al [10] has characterized and evaluated the microfractures in coal induced by high pressure CO 2 fracturing and determined the micronanoscale damage through field emission scanning electron microscopy (FESEM), considering that the first step of the mechanism of CO 2 gas impact crushing coal matrix is CO 2 gas beam destroyed cleat Effect of supercritical CO2 transient highpressure fracturing

.jpg)

Petrological, mineralogical, and geochemical compositions of coal

2022年9月1日 Exploring the landcover types and their changes in openpit mining areas is of great significance to the ecological restoration of Ordos City and its sustainable development