Stone Crushing Particle Size And What About

Effects of particle gradation and material proportions on the

Different gradations, especially the changes in fine particle content and the continuity of particle size distribution, are the main reasons for the decline in the mechanical properties of crushed stone roadbed [6]2020年3月1日 In this study, singleparticle crushing tests were carried out on rockfill materials with nominal particle diameters of 25 mm, 5 mm and 10 mm to investigate the particle size Effects of particle size on crushing and deformation behaviors 2024年10月3日 A complete set of studies on crushed stone aggregates was carried out to investigate particle crushing characteristics under various stress path conditions To quantify Investigation of the particle crushing characteristics of stacked stone 2020年10月28日 Experiments on the compaction of crushed stone were carried out by considering the impact of particle size and gradation to examine the strength and particle The Bearing and Breakage Characteristics of Crushed Stone

Investigation of the particle crushing characteristics of

2024年10月3日 The particle crushing behavior of stacked stone mate rials during testing is inuenced not only by stress levels and magnitudes but also by stress paths (Gupta2024年10月24日 The results show that the crushing probability of particles is related to the impact energy and particle size, and the strength of particles increases with the decrease of Experimental Study of the Crushing Characteristics of Single Particle 2024年7月14日 Based on the simulation results of 45 rockfill particles with real morphology, this section focuses on the influence of four main morphological parameters, sphericity, aspect Influence of real particle morphology on single particle crushing 2021年11月24日 采用多面体颗粒近似真实堆石料颗粒的不规则棱角状形状,并通过Voronoi空间划分将母颗粒离散成若干多面体子颗粒,子颗粒间通过接触面上的内聚力模型(CZM)胶结发 堆石料颗粒破碎强度的尺寸和形状效应隐式离散元研究

.jpg)

Experimental Study on Fractal Characteristics of

2022年10月13日 In order to clarify the effects of water content and cyclic compaction on the compaction and fractal characteristics of the particle size distribution of graded crushed stone, several samples with different water 2024年6月28日 The results indicate that the stress–strain curves of crushed stone with different particle sizes and Talbot coefficients exhibit similar nonlinear behavior during confined Study on compaction characteristics and mechanical model 2024年6月28日 During the preparation of the sample, waste stone particles of three colors (with a particle size of 20–40 mm) were added to analyze the crushing condition of waste stone after compactionStudy on compaction characteristics and mechanical model 2024年2月29日 Fundamental research on singleparticle breaking and the uniaxial compressive strength (UCS) of carbonaceous mudstone aggregates at different water contents was carried out to investigate the relationship between the singleparticle crushing strength and UCS Based on elasticity theory and the superposition principle, a shape factor α was introduced to propose a Study of the uniaxial compressive strength of watersensitive

.jpg)

Particle size distribution of coal and gangue after impact

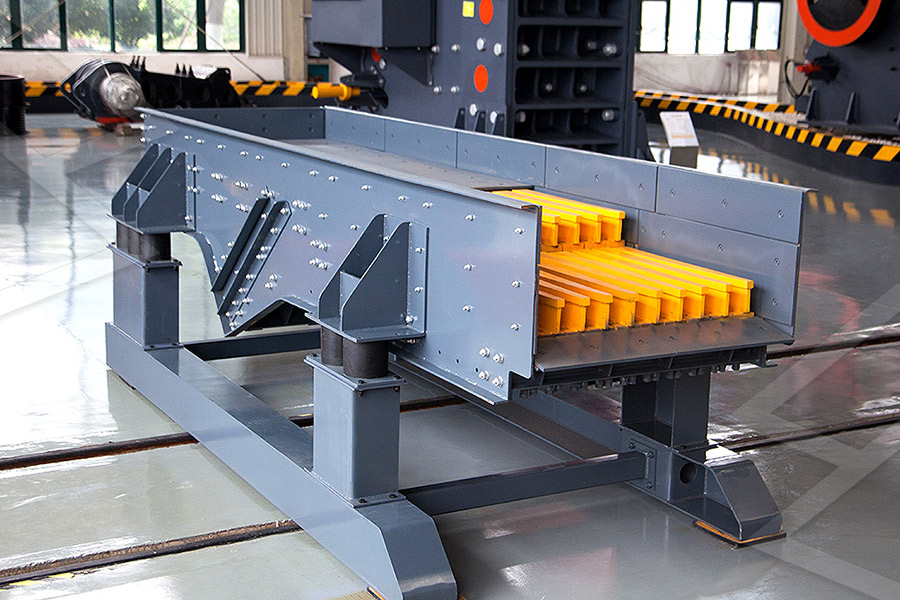

2017年7月9日 Based on the separation and backfilling system of coal and gangue, the mineral material impact experiments were conducted utilizing the hardness difference between coal and gangue according to the uniaxial compression experiments The broken coal and gangue particles were collected and screened by different size meshes The particle size distributions of coal 2022年5月13日 The design of stone crusher for crushing particle size between 25–135 mm to about 24–202 mm was doneANSYS software is used to find out high region stress area as major factor for safe working of proposed equipment 2020 Tauyanashechikuku et al[24] Zimbabwe 13 Secondary crusherStone Crushers: A Technical Review on Significant Part of 2023年9月2日 During the stone crushing operation, large size stone, mined from quarries in the size range of 200–300 mm, is crushed to smaller usable sizes, generally 6, 12, or 25 mmParticulate Matter from Stone Crushing Industry: Size2006年3月1日 A cluster of 50 stone crushing units located at Pammal, in suburban Chennai, the capital of Tamil Nadu State, India, is a source of high levels of dust generation in the vicinity of the crushers and in the communities surrounding them Ambient air quality network consisting of 26 sampling locations were operated to continuously monitor the total and respirable particulate Particulate Matter from Stone Crushing Industry: Size

The Stone Crushing Business in Pakistan: Opportunities and

2024年10月24日 The stone crushing industry in Pakistan plays a vital role in supporting the country's burgeoning construction and infrastructure development sectors As a thriving segment of the economy, this industry is primarily concentrated in the northern regions of the country, particularly in the resourcerich provinces of Khyber Pakhtunkhwa and Punjab 2024年7月26日 Relation between Feed size and Shape The greater reduction ratio the worse particle shape Inter particle breakage improves shape When crushing a bed of material weaker particles will break first Flaky or elongated particles are weaker then round Breaking round particles gives flaky material F l a k i n e s s i n d e x [%] Particle size [mm]Crushing Principles of Mechanical Crushing 911 A cluster of 50 stone crushing units located at Pammal, in suburban Chennai, the capital of Tamil Nadu State, India, is a source of high levels of dust generation in the vicinity of the crushers and in the communities surrounding them Ambient air Particulate Matter from Stone Crushing Industry: Size Distribution and 2020年2月8日 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone The L18 orthogonal array has been used to investigate how the CSS, throw, eccentric speed, and particle size affect the products of the cone of the crusher (its cumulative weight fraction) The CSS, as well as the Aggregate Production Optimization in a StoneCrushing

Emission of respirable dust from stone quarrying, potential health

2021年8月28日 Sample collection and analysis Bakhrija quarry is surrounded by a number of stone crushing units (≈ 25 units) around it Samples of suspended particulate matter (PM 25 and PM 10) were collected from four locations in and around Bakhrija mines during the premonsoon season (June 2019)During the sample collection, the ambient temperature varied from 43 to 2020年3月1日 Particle size has a great influence on the fracture strength of rockfill materials Discrete element modeling of the singleparticle crushing test for ballast stones Computers and Geotechnics, 88 (2017), pp 6173 View PDF View article View in Scopus Google Scholar Wang and Coop, 2016Effects of particle size on crushing and deformation behaviors 2023年11月17日 The crushing of particles reduces particle size and the generated fine fragments fill the interparticle voids, yielding a more compacted specimen Meanwhile, the continuous breakage of particles creates irregular shape particles which tend to strengthen the interlocking effect and cause dilation The two mechanisms compete during the shearing The critical state of crushable granular sand Acta 2024年10月14日 Here, you'll discover 11 stone crushing equipment needed for stone crushing, from primary crushers to fine crushers and conveyor belts 1 Jaw crusher Jaw crushers are primary crushers utilized in the first stage of stone crushing They are commonly found in various stone crushing plants worldwide, from Nigeria to the USA, UK, and IcelandWhat Machines Do Stone Crushing Plants Need? Fote

Particle breakage and its mechanical response in granular

2023年12月15日 To explore the particle breakage mechanism, many researchers have conducted a series of experiments to observe the mechanical response of granular soils under the influence of breakage These experiments can be categorized according to the test conditions into singleparticle crushing, groupparticle crushing, and bondedparticle crushing2023年12月1日 The crushing ratio of the compressed crushed stones increases with increasing particle size Furthermore, the proportion of crushed particles tends to develop to the next smaller size of the crushed stones, and the percentage content Effects of particle size on compressive deformation 2013年1月5日 The generation and emission of particulate matter from abrasion industry are subjects of the pollution monitoring by multidisciplinary study involving earth sciences and engineering disciplines This work investigates the correlation between textural properties of in situ rock with class size distribution and morphology of particles generated after rock The assessment of particulate matter emitted from stonecrushing Particle size distribution is considered to be a key indicator for evaluating the physical properties of crushed stone aggregate [4,5] Different gradations, especially the changes in fine particle content and the continuity of particle size distribution, are the main reasons for the decline in the mechanical properties of crushed stone roadbed Effects of particle gradation and material proportions on the

All about Msand Rudra Infratech

Feeding hard stones of various sizes into primary and secondary crushers to decrease their size Crushing hard granite stones into fine particles using stateoftheart international technology Washing and grading the crushed particles to obtain fine particles of the desired shape and size Advantages of Msand2024年4月24日 To improve the crushing effect and reduce the range of particle size distribution after crushing, the crushing mechanism and the particle size distribution pattern after crushing of sintered ore under different roller rotation speeds are analysed in this paperCrushing mechanism analysis of sintered ore and study of particle size Particle size distribution is considered to be a key indicator for evaluating the physical properties of crushed stone aggregate [4, 5] In order to explore the compressive strength and crushing evolution of crushed stone ballast particles, domestic and foreign experts and scholars have proposed a variety of research methods, Effects of particle gradation and material proportions on the 2024年10月6日 Efficient Stone Crushing for All Types of Materials Our advanced stone crushers are designed to crush a wide range of materials, from soft limestone to the hardest granite and bridges They help in achieving the desired particle size and shape required for these infrastructure projects Recycling Industry In the recycling industry, stone Stone Crusher Rock Crushing Machine

.jpg)

Crushing Principles of Mechanical Crushing 911

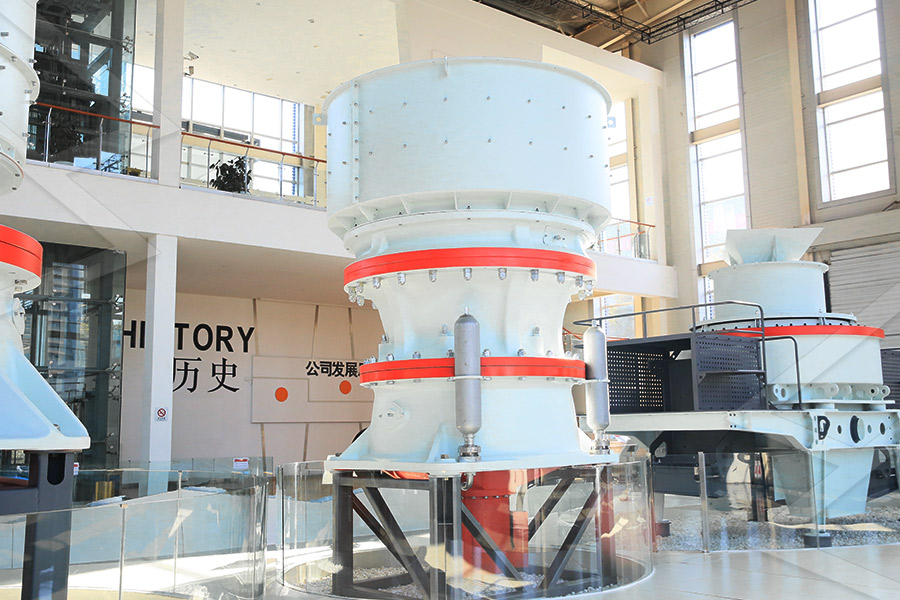

2024年9月24日 • Relation between Feed size and Shape – The greater reduction ratio the worse particle shape – Inter particle breakage improves shape When crushing a bed of material weaker particles will break first Flaky or elongated particles are weaker then round – Breaking round particles gives flaky material F l a k i n e s s i n d e x On 6 September 2018, at 3:08 am JST, the Hokkaido Eastern Iburi Earthquake (M w 66 and M j 67) (Japan Meteorological Agency, 2018) occurredThe Ministry of Land, Infrastructure, Transport, and Tourism (MLIT, 2018) stated that this earthquake had the largest area of slope failure (approximately 44 km 2) among all the earthquakes that had occurred since the Particle crushing and critical state of volcanic pumice – 2018 2006年3月1日 A cluster of 50 stone crushing units located at Pammal, in suburban Chennai, the capital of Tamil Nadu State, India, is a source of high levels of dust generation in the vicinity of the crushers and in the communities surrounding them Ambient air Particulate Matter from Stone Crushing Industry: Size The OSS is the largest distance between the concave and the mantle at the bottom of the crusher, so it determines the largest particle size of the outgoing product As the smallest distance between the concave and the mantle, the CSS is the final crushing zone, and is vital for determining the product size, as well as energy consumption and Cone crusher basics in 4 minutes SRP

.jpg)

Aggregates SpringerLink

2021年3月3日 The main reason for several stages of crushing is the limited reduction ratio available with a single crusher In crushing terminology, this parameter can be commonly defined as “the ratio of maximum particle size entering to maximum particle size leaving the crusher” The type of crusher influences the size and the shape of the aggregate 2024年4月23日 ing the crushing probability of particles within the ballast group under various stress conditions This is achieved by calculating the particle crushing strength [3 –5] Owing to its genesis through the random fragmentation of solid rock, ballast exhibits inherent variability in terms of particle size and shapeBallast crushing probability model considering the 2022年4月20日 Classification: Limestone is processed into finished products of various specifications through impact crushing according to user requirements The particle shape is good and can be classified by vibrating screen The particle size of limestone crushing is very small after coarse crushing and medium and fine crushingLimestone crushing and grinding production line SBM 2021年11月3日 (PM10) levels in ambient air The particle size study indicates high percentage of finer particles and silica when compared to the Stone crushing operations emitting silica dust in general have adverse environmental impacts Hall et al, (1993) and Fuglsang (2002), underground mining impacts Effect of Particulate Matter on Stone Crushing Sites

.jpg)

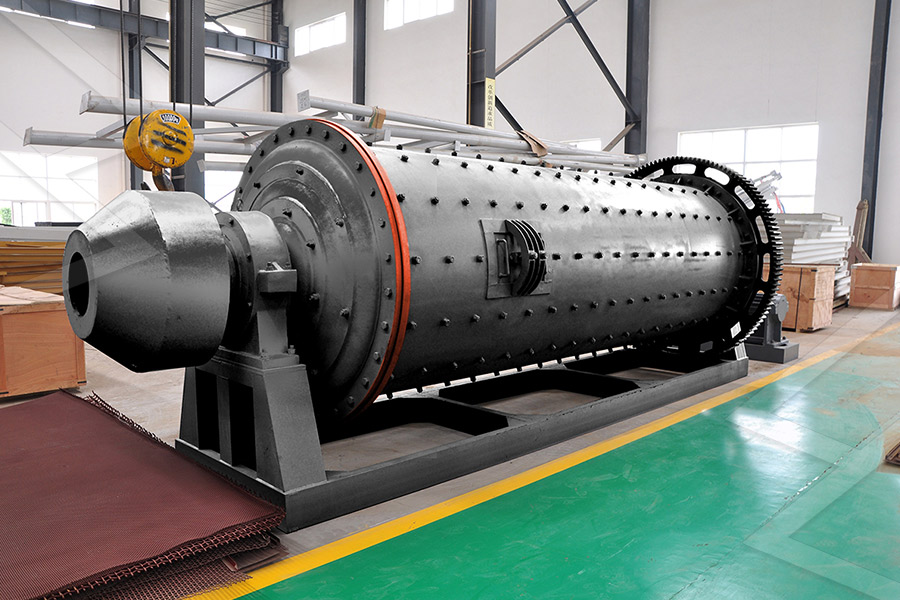

A GUIDEBOOK TO PARTICLE SIZE ANALYSIS Horiba

2016年9月20日 technologies also require lab measurements to track changes in particle size including crushing, homogenization, emulsifi cation, micro fl uidization, and others Separation steps such as screening, fi ltering, cyclones, etc may be monitored by measuring particle size before and after the process Particle size growth may be2024年3月1日 depend on desired input particle size, the feed rate and maximum output particle size The specification for is 120mm, width, W, of each roll is 150mm, and the maximum roll gap, l, is 5mm 213 Maximum Size of the Particle that can be Fed into the Roll Crusher The maximum size of the particle that can be fedDesign, Fabrication and Testing of a Double Roll Crusher2023年10月10日 Therefore, continuous particle size stones shall be used What are the continuous particle size stone crushing equipment? The PE jaw crusher, PF impact crusher, HPT cone crusher, VSI6X impact crusher and K series mobile crusher under the crushing family of SMMVIK Machinery can crush hard stones to the required particle size at one time Not Why should continuous grade stones be used for pumping 2021年8月15日 Reducing the CSS leads to more crushing and, thus, a smaller particle size distribution in the product stream However, this reduction comes at the cost of a smaller processing capacity Bai et al (2019) reported an attempt to establish a framework to measure and visualize the sustainability of stone mines The authors used the concept of A review of modeling and control strategies for cone crushers

.jpg)

Effect of duration and type of grinding on the particle size

2023年10月1日 Its particle size distribution before being subjected to any grinding, but after crushing with a jaw crusher was measured by a particle size analyzer The oxide composition of pumice and lime used in this study was determined via X 2024年1月25日 for evolving particle size, where the influence of particle shape is largely neglected However, the critical state friction angle has been found dependent on the overall shape regularity in a mixture of angular sand and rounded glass beads [36, 55, 58] This suggests the necessity to consider particle shape effect in conjunction with breakageThe critical state of crushable granular sand Springer2023年11月28日 Ballast is coarse aggregate with particle size normally ranging from 10 mm to 65 mm Upon repeated train loading, ballast deteriorates in the form of either continuous abrasion of sharp corners or size degradation, which have been reported as the fundamental cause for the instability of railway tracks In this study, the splitting behavior of ballast grain with varying Effects of Particle Size and Grading on the Breakage of 2022年9月29日 This study examines the particle size and distribution of the main chemical components of gangue during the crushing process Coal mine gangue was chosen as the research object, and its particle Experimental Investigation of Particle Size Alteration and the

.jpg)

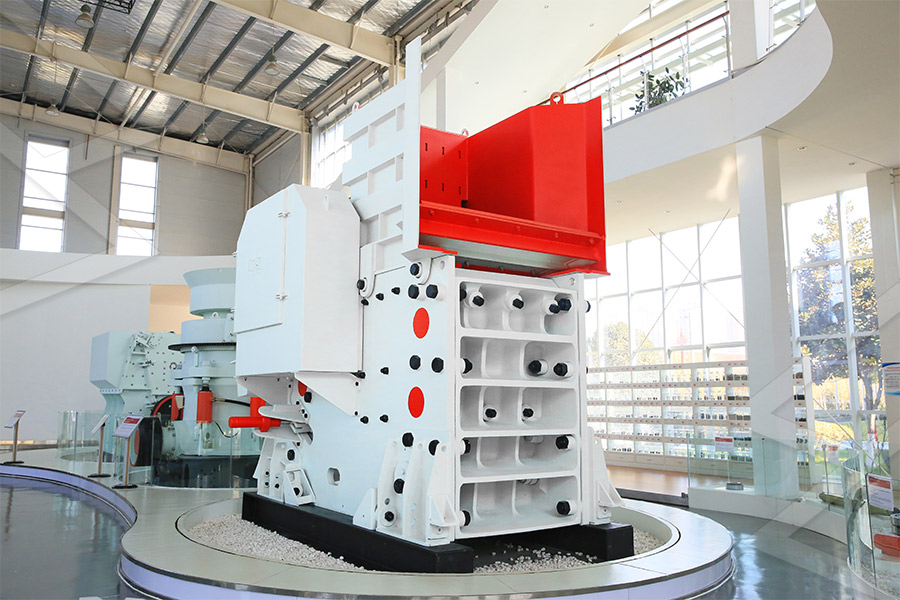

Limestone Crushing And SandMaking Plant Eastman Rock

2024年1月11日 The hammer crusher is a crushing processing equipment for limestone This equipment can replace the rough crushing process of the stone crusher, directly crushing limestone into particles below 25mm The hammer crusher adopts a dual motor operation, consisting of a plate hammer and a rotor to form a crushing powerParticulate Matter from Stone Crushing Industry: Size Distribution and Health Effects R Sivacoumar1; R Jayabalou2; S Swarnalatha3; and K Balakrishnan4 Abstract: A cluster of 50 stone crushing units located at Pammal, in suburban Chennai, the capital of Tamil Nadu State, India, is a source of high levels of dust generation in the vicinity of the crushers and in the (PDF) Particulate matter from stone crushing industry: size