Power Rating For T Ball Mill

Ball Mill Design/Power Calculation 911Metallurgist

2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed 2001年8月1日 Typical power consumption for a 5m diameter by 7mlong ball mill is between 25 and 35 MW The actual proportion of this energy usefully used in size reduction is thought Charge behaviour and power consumption in ball mills: 2015年10月19日 Unlock the secrets of ball mill motor power draw with 911 Metallurgist This comprehensive guide covers sizing and design formulas, providing essential insights to Ball Mill Motor Power Draw Sizing and Design Formula2024年10月13日 Motor Power: The motor power of a ball mill is an important factor in determining its grinding capacity Ball mills can be equipped with motors ranging from 10 kW Technical specifications and selection guide for ball mills

.jpg)

Mill drives: the desire for increased power and the

Accordingly, the latest 40 ft dia SAG mill is rated at 29 MW and 78% CS, with a 42 ft dia mill built but not yet operational The more recent option of operating at higher ball charge volumes 2022年3月15日 In this study, having the optimal d80 for the concentration unit, the mill data, and utilizing the Excel Software and Morrell method, first the total power for the optimal set of d80 was(PDF) Power consumption management and 1990年2月1日 Development of an equation for tumbling charge and balls plus comparison to plant data suggests that the net mill power for cylindrical semiautogenous millA mill power equation for SAG mills Mining, MetallurgySAG Mill power draw models are used in mill design and grinding circuit modelling to predict how much power will be consumed by a particular mill geometry and operating configuration This A comparison of SAG mill power models

.jpg)

Consolidation and validation of several tumbling mill power

2010年11月1日 The JKMRC has developed effective models for predicting ball mill, au1ogenous mill, semi autogenous mill and crusher power draw When combined with comminution models 2021年2月24日 Comparison between the specific grinding energy (w) from the various methods In the next Figure a comparison is made between the specific grinding energy (w) values, MODELING THE SPECIFIC GRINDING ENERGY AND BALL the desired motor power and drive rating, the maximum design mill speed, and the maximum design ball charge volume (Barratt, 1989) For single pinion and dual pinion drives, with 21 MW now a distinct possibility, the probability of pinion changes to a higher mill speed should always be considered when setting gear ratios, service factors, and Mill drives: the desire for increased power and the2024年10月13日 Motor Power: The motor power of a ball mill is an important factor in determining its grinding capacity Ball mills can be equipped with motors ranging from 10 kW to 500 kW or more, depending on the size and desired output of the mill Speed: Ball mills are usually operated at speeds between 60% and 70% of the critical speedTechnical specifications and selection guide for ball mills

Gearless mill drives ABB

2024年3月17日 Larger ball and SAG mills, with higher installed power ratings relative to the mill diameter, offer higher efficiency and throughput, roundtheclock reliability and the opportunity to mine in remote areas This makes low ore grades economical to grind ABB has delivered some of the world's largest GMDs: • 22 MW GMD for 28’ ball mill2020年7月2日 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls segregation in a (PDF) Effects of Ball Size Distribution and Mill Speed and 2017年1月15日 Number of particles used in simulating 30 cm slices of mills with different diameters (balls in size range of 40–15 mm) and powder following the cumulative size distribution given by Passing (PDF) A Review of Advanced Ball Mill Modelling ResearchGate2024年1月13日 Figure 1 Showing electrical energy and embodied energy for different types of tumbling mills Adapted from [2] Recently, it was realised that highgrade ores are depleting fast and are almost Grinding Media in Ball MillsA Review ResearchGate

.jpg)

(PDF) Grinding Media in Ball MillsA Review ResearchGate

2023年4月23日 One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their propertiesThe proven classical option for cement grinding Whether employed as a twocompartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding Used in combination with the sepol® highefficiency separator, ball mills can reliably Ball Mill thyssenkrupp Polysius2016年10月23日 VBELT Ball Mill DRIVE Vbelt or polyV drives are generally used on grinding mills consuming 350 HP or less Where power exceeds this, drives become so large and motors become special, resulting in an uneconomical application Generally the driven mill sheave is of split hub construction to facilitate field assemblyBall Mill Drives 911Metallurgist2023年3月1日 This paper investigates grinding media's dynamic voidage to improve the MorrellC model's accuracy in predicting the ball mills’ power draw Using a threelevel factorial design, we provided an empirical model to determine the voidage of each ball size distribution proposed by Bond for ball mills’ first filling in various ranges of Improving the Morrell Cmodel's accuracy in predicting the ball mills

.jpg)

MODULE #5: FUNCTIONAL PERFOMANCE OF BALL

2018年12月9日 There are two "inputs" to a ball mill circuit: the ore fed to the circuit and the power delivered by the grinding mill A ball mill circuit has two "efficiencies": that of the ball mill grinding environment* and that of the classification system* A ball mill circuit has two efficiencies because it has two main functions:2024年10月22日 In this thesis, a procedure for predicting the charge motion and the power draw of a ball mill based on the discrete element method (DEM) is calibrated and validated by means of photographs of the charge, and power draw measurements of a 1:5scale laboratory mill, which were kindly provided by the company Magotteaux International SA University of Liège uliege2024年10月13日 The ball size distribution in ball mills plays a crucial role in the grinding process, affecting the energy consumption, capacity, and efficiency of the mill 1 Ball Size Distribution in Ball Mills: The ball size distribution in a ball mill refers to the range of ball sizes used in the mill It is typically represented as a cumulative Ball size distribution in ball mills: Optimization and impact on 2006年1月1日 The relining time also reduced by 375% with the new liners Powell et al, 2006; Rajamani, 2006;Yahyaei et al, 2009;MalekiMoghaddam et al, 2013;MalekiMoghaddam et al, 2015;Cleary and Owen (PDF) Selection and design of mill liners ResearchGate

.jpg)

Understanding ball mill specifications for optimal

2024年10月13日 The total horsepower (HP) of the ball mill is a critical specification that indicates the power required to drive the mill The HP is influenced by the mill diameter, length, and rotation speed A higher HP mill is capable of processing more material per hour but may also require a more powerful motor and a larger foundation 3 Rotation Speed:2021年3月12日 Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide significant cost and CO 2 emission benefits to the cement producer n by Thomas Holzinger, Holzinger Consulting, Switzerland BALL MILLS 1 FEBRUARY 2021 INTERNATIONAL BALL MILLS Ball mill optimisation Holzinger Consulting1 天前 Figure 1 : Grinding Power to produce various product sizes in a Ball Mill (9mm balls) and an Isa Mill (2 mm sand) (for KCGM pyrite concentrate) Chemistry Impacts The use of inert grinding media gives a crucial advantage to stirred milling in fine flotation and leaching applications Even if it were economic to grind to 10 microns in a steel Fine Grinding as Enabling Technology – The IsaMill2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and (PDF) Grinding in Ball Mills: Modeling and Process Control

.jpg)

Bond´s work index estimation using nonstandard ball mills

2023年9月18日 The Bond work index (BWI) is a wellknown method used when selecting comminution equipment, to evaluate the grinding efficiency and to calculate the required grinding power2022年1月1日 Analysis on energy transfer during mechanical coating and ball milling—supported by electric power measurement in planetary ball mill Int J Miner Process, 121 (2013), pp 5158, 101016/jminpro201303003 View PDF View article View in Scopus Google Scholar [6]Effects of balltopowder diameter ratio and powder particle The depth of the centrifuged layer increases with the mill speed N 52 Variation of torque and power with mill speed Fig 2 shows the variation of the average torque and power with mill speed for the ball mill described above with a fill level of 50% The torque increases slowly until the peak is attained around N s 80%Charge behaviour and power consumption in ball mills: 2023年10月2日 ball mill s it is common pra ctice for ope rators to c harge balls to a power setpoint As ball mills often have very stable power draw , in some cases it may be assumed that the bal l charge (PDF) RealTime Estimation of SAG Mill Charge

The effect of ball size distribution on power draw, charge

2017年7月1日 The results showed that at a constant mill filling, the power draw was changed with changing the ball size distribution and for all mill fillings the maximum power draw occurred when the fraction 2023年8月15日 The circulating load of the ball mill refers to t he mass percentage of the return to the fresh feed Power/ kW 430 Throughput (t/h) 50150 50160 Classification pressure (Mpa) 01 (PDF) Supplementary Relationship between Circulating Load United Nuclear , Scientific Equipment Supplies : Ball Mills Radiation and Nuclear Element Samples Lab Equipment Electronic Electrical Science! Printed Products Chemicals Metals Neodymium Magnets Area 51 Glow In The Dark, UV IR Lab Glassware Containers Specials, Oneoffs, Surplus What's New Radiation and Nuclear Chemistry Tools And Equipment Ball Mills : United Nuclear , Scientific Equipment Supplies, 2022年7月21日 gear transmission The gearless ball mill has emerged Because of its massive volume, the gearless ball mill is difficultto manufacture and maintain Therefore, a novel module combined permanent magnet motor with wrapped type for mine ball mill (MBMWT‐MCPMM) is proposed, eliminating the gear and reduction box in the traditional drive mode andElectromagnetic design and thermal analysis of module

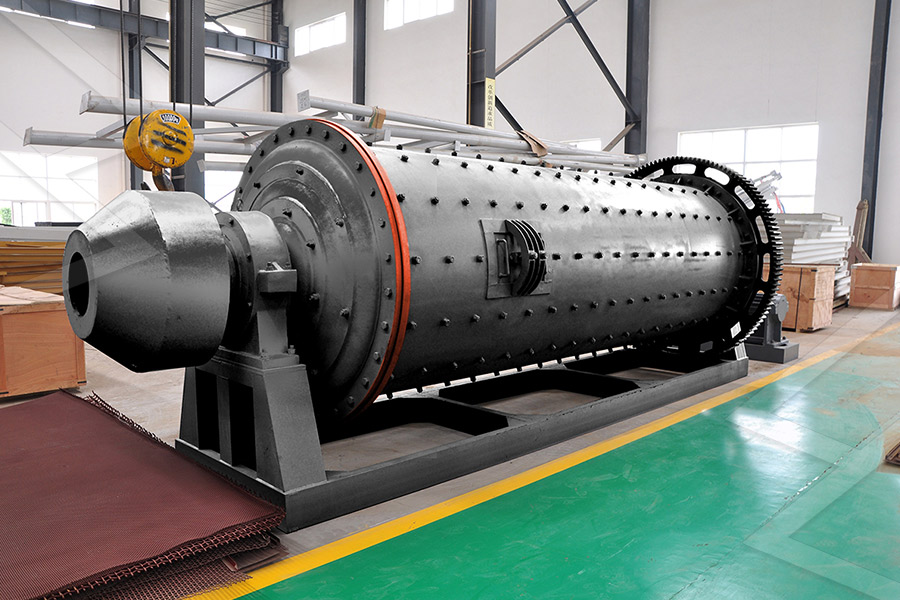

Ball Mills and Ball Charging Bulk Handling Technologies

This design uses heavy duty support rollers to drive the rotation of the mill shell directly Depending on the, the drive and support rollers can be polyurethane lined rollers or a series of rubber tyres Bulk Handling Techonolgies can design and supply roller mounted ball mills with capacities ranging from 500 kg/hr up to 25 TPH in a single mill2001年8月1日 Discrete element method (DEM) modelling has been used to systematically study the effects of changes in mill operating parameters and particle properties on the charge shape and power draw of a 5m ball mill Specifically, changes in charge fill level, lifter shape (either by design or wear) and lifter pattern are analysed The effects of changes to the properties of the Charge behaviour and power consumption in ball mills: 2019年1月30日 Mill power models have been used in a variety of ways in industrial practice since power directly equates to throughput and fineness of ground product We first start with HoggFuerstenau Power Model and show how this model successfully predicted the power draw of many grinding mills in several mining operations Then, we show how this model was on the The Evolution of Grinding Mill Power Models Springer2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as A Review of the Grinding Media in Ball Mills for Mineral

Temperature Reduction for Ball Mill

Power generation; Pulp and Paper Industry; Shipbuilding industry Nozzle solutions and systems for civil shipping; A ball mill’s cylindrical shell is filled with large cylindrical pellets made of some material (typically stainless steel, 2017年2月1日 from the boundary of a ball mill from the load: (i) direct heat transfer from the l oad to wall, (ii) h eat transfer from the air to the wall, and (iii) heat transfer between the load and the gasHeat generation model in the ballmilling process of a tantalum 2020年2月26日 Measurement results of two ball mills in a real ceramic manufacturing plant showed that the proposed calculation models could achieve an accuracy of more than 96% for predicting the ball mill Calculation method and its application for energy consumption of ball 2024年10月25日 Reason: This is a common problem mining ball mills face, resulting in low productivity and low ore processing efficiency One reason may be the improper design of the grinding chamber, which affects the flow of materials and reduces grinding efficiency Additionally, worn or damaged liners can hinder the grinding process by reducing the effective impact Inventory Of Common Faults And Solutions Of Mining Ball Mill

.jpg)

(PDF) Effects of balltopowder diameter ratio and powder

2021年12月1日 The effects of the balltopowder diameter ratio (BPDR) and the shape of the powder particles on EDEM simulation results and time in the planetary ball mill was investigated2018年11月1日 The ballmills in SABC circuits are operated at a relatively high speed (70–78% of critical speed), with large balls (50 mm to 80 mm), to cope with a coarse feed (a transfer size from the SAG mill typically larger than 10 mm) and to maximize power draw Overflow ballmills are often used and a mixture of ball sizes is used to top up the ball Addition of pebbles to a ballmill to improve grinding Browse planetary ball mill equipment for sale at MSE Supplies We also carry highquality laboratory ball mills, mill systems, necessary media, and more Free Shipping on MSE PRO Online Orders of $500 or More! US Orders Only * Offer Excludes Hazmat Shipments * Call Us: +1 (520)7896673 Sign in or Create an AccountLaboratory Ball Mill, Planetary Ball Mill– MSE Supplies LLC2017年8月27日 J Control Theory Appl 2013 11 (3) 454–462 DOI 101007/s1176801312103 Intelligent optimal control system for ball mill grinding process Dayong ZHAO 1†, Tianyou CHAI,2 1State Key Laboratory of Synthetical Automation for Process Industries, Northeastern University, Shenyang Liaoning , China;Intelligent optimal control system for ball mill grinding

Factors Affecting Ball Mill Grinding Efficiency 911Metallurgist

2017年10月26日 a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account As well, mills with different length to diameter ratios for a given power rating will yield different material 2022年12月22日 The ball mill is also suitable for the JK model, where tests on monosized feed samples are conducted to investigate the effect of feed particle size on ore breakage results Shi et al performed ball mill breakage characterization and developed a ball mill breakage model using new ore The JKFBC test relates to ball mills in the sense that An EnergyT75 Size Reduction Model for Ball Mills Springer