Secondary Crushing Unit Introduction In India

.jpg)

Pollution Control Board, Assam

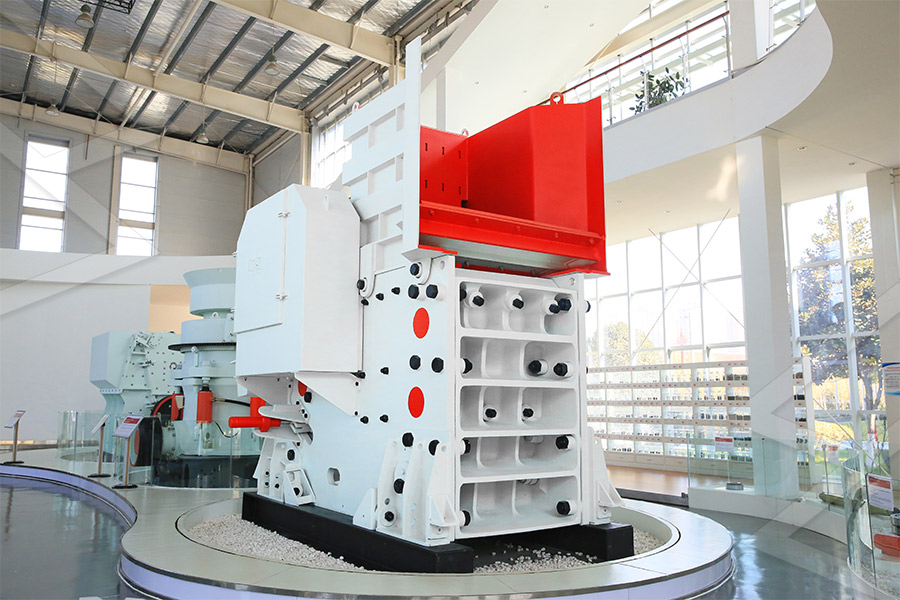

2024年7月9日 33 Secondary crushing: After primary crushing, crushed stones are fed to secondary crushers through conveyor belts In this stage, stones are further crushed to a size 2022年5月13日 1 Introduction Crushers are widely used equipment to reduce the large size rocks into stones finer than about 50–100 mm in size [1] In infrastructure industry, these Stone Crushers: A Technical Review on Significant Part of 2022年5月14日 Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones It normally highlights a huge crushing rate and high return Stone Crushers: A Technical Review on Significant Part of2023年5月26日 Stone crushing unit should obtain Consent to Establish (CTE) and Consent to Operate (CTO) from the concerned SPCB/PCC Stone crushing unit shall comply with emission norms prescribed under the Environment CPCB’s new guidelines for India’s stone crusher

.jpg)

Understanding Effects of Crushing Mechanism on

2019年10月24日 The aggregates were collected from two different types of crushers (i) the first crusher had jaw, cone and vertical shaft impactor (VSI) as primary, secondary and tertiary 2018年2月27日 size, suitable for transport and for feeding the secondary crushers or auto genius grinding or semi auto genus grinding mills; which will discuss in due course of time So, Introduction to Mineral Processing Prof Arun Kumar 2018年11月19日 over 12,000 stone crusher units in India The number is expected to grow further keeping in view the future plans for development of infrastructure of roads, canals and Comprehensive Industry Document Stone Crushers2023年5月31日 Stone crushing units have long been recognized as major contributors to fugitive dust emissions and severe air pollution In response to the growing concern, the Central CPCB’s New Guidelines for India’s Stone Crusher Sector

.jpg)

Optimizing processing parameters of stone crushers through

2022年1月1日 Present paper showcase the optimization of crushing parameters through Taguchi methods to improve the production yield of the aggregate produced The main 2022年7月22日 In India, among the small scale industries, stone crushing industry plays an important role In each taluk, 10 per cent of stone crushing units have been selected From each unit, 4 workers are selected for constituting the sample size of 120 workers The study This study is based on both primary data and secondary data The primary data SOCIOECONOMIC AND ENVIRONMENTAL IMPACT OF 2019年2月28日 Since after the introduction of the potato in India in the early seventeenth century by the Portuguese traders, the potato has been widely grown and consumed in the countrystatuschallengesandsolutionsofoilseedproductioninindia2017年4月18日 The quality products manufactured by Tech Makkers is Jaw Crusher, Portable Crushing Unit, Cone Crusher, Vertical Shaft Impactor, Vibrating Screen Tech Makkers offers jaw crushers, which are designed for consistent Jaw Crusher Manufacturer, Jaw Crusher India,

.jpg)

Assessment of Occupational Dust and Silica Exposure in Indian

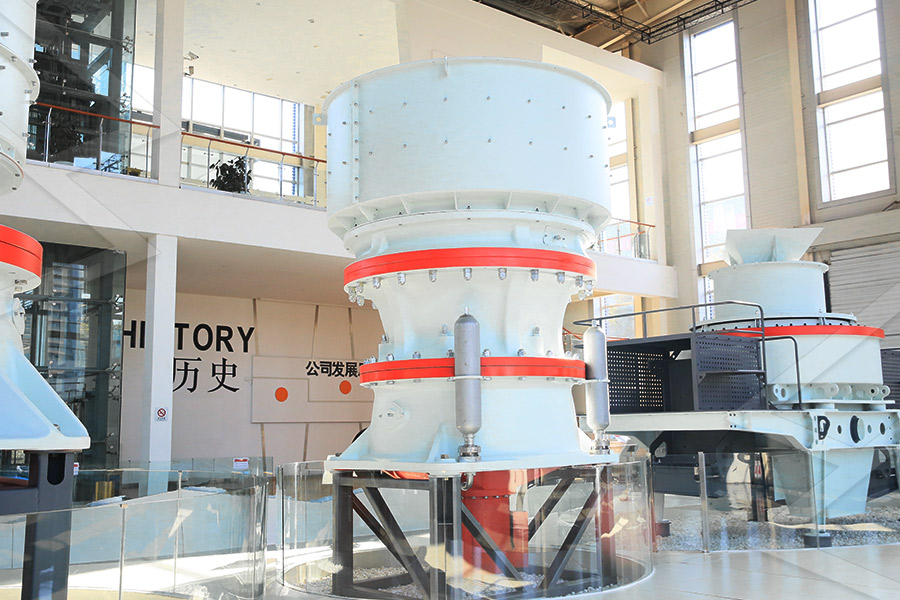

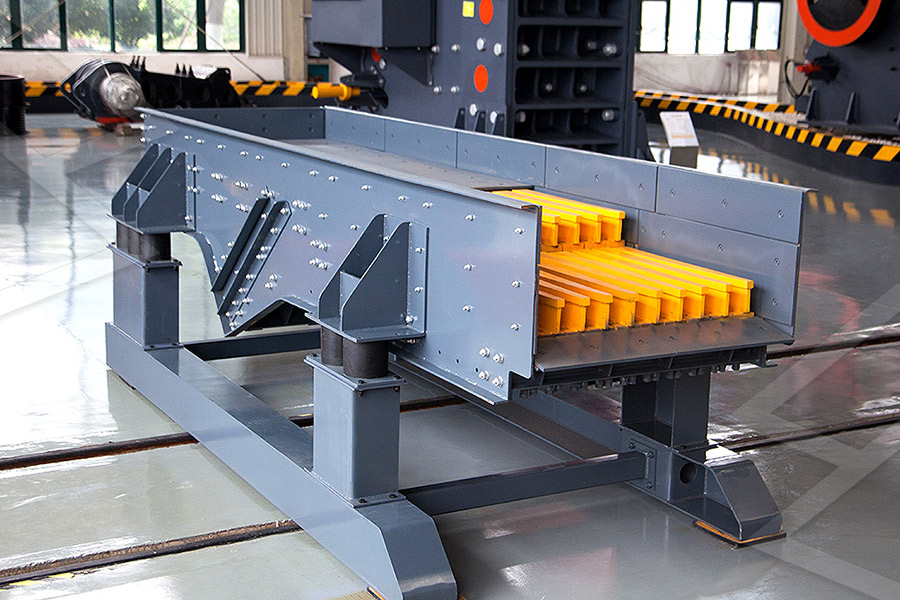

2017年12月27日 A cluster of 50 stone Crushing units located at Pammal, in Suburban Chennai, the capital of Tamil Nadu State, India, is a Source of high levels of dust generation in the vicinity of the crushers 2024年1月18日 The secondary crushing operations in rock quarrying include one of the main stages in obtaining industrial rock aggregates with different size fractions Of the crushingCOMPARISON OF SECONDARY CRUSHING OPERATIONS 2017年12月3日 Introduction Metal and masonry stone, building material, etc play a vital role in urbanisation 1 and today’s stone mining and crushing have become the backbone of infrastructure development in India 2–4 The finished product of stone crushing units in the form of crushed stone, stone chips of various sizes; plays a crucial role as a raw material for various Assessment of Occupational Dust and Silica Exposure in Indian 2024年7月9日 33 Secondary crushing: After primary crushing, crushed stones are fed to secondary crushers through conveyor belts In this stage, stones are further crushed to a size of 4060 mm to 10 mm or even smaller Stone crushing units use different types of crushers for secondary crushing Granulator or cone crusher is usually used for secondary crushingPollution Control Board, Assam

.jpg)

Assessment of Occupational Dust and Silica Exposure in Indian

2017年12月3日 Introduction Metal and masonry stone, building material, etc play a vital role in urbanisation 1 and today’s stone mining and crushing have become the backbone of infrastructure development in India 2–4 The finished product of stone crushing units in the form of crushed stone, stone chips of various sizes; plays a crucial role as a raw material for various 11 Introduction India has emerged a leading producer of certain food products such as buffalo meat, black tea, milk, and fruit and vegetables with secondary and tertiary sector contributing about 40% of the total value addition In 19992000, there were 91,000 rice hullers, and 2,60,000 small flour mills engaged in primary milling Food TechnologyI: Lesson 1 INTRODUCTION TO FOOD PROCESSING IN INDIA2 天之前 Introduction Crushing is the first mechanical stage in the process of comminution in which the main objective is the liberation of the valuable minerals from the gangue for the mineral processing department to crush and handle the ore from this point through the successive oreprocessing unit operations Secondary crushing includes all Chapter 6: Crushers GlobalSpec2024年1月11日 to a size of 4060 mm to 10 mm or even smaller Stone crushing units use different types of crushers for secondary crushing Granulator or cone crusher is usually used for secondary crushing 34 Screening: From secondary crusher, crushed stones are transferred for screening through a conveyor beltEnvironmental Guidelines for Stone Crushing Units

.jpg)

Sugarcane Agriculture and Sugar Industry in India: At a Glance

2014年2月1日 The Indian sugar industry plays a leading role in global sugar market, it being the world’s second largest producer after Brazil producing nearly 15 and 25 % of global sugar and sugarcane, respectively It is a significant contributor to the socioeconomic development of the nation The sugar industry which encompasses 597 operating sugar mills, 309 distilleries and 2023年8月8日 to a size of 4060 mm to 10 mm or even smaller Stone crushing units use different types of crushers for secondary crushing Granulator or cone crusher is usually used for secondary crushing 34 Screening: From secondary crusher, crushed stones are transferred for screening through a conveyor beltEnvironmental Guidelines for Stone Crushing Units py2021年3月3日 The building and construction market consumes the majority of the total resource consumption of the world It produces one third of all waste ( Fig 192), which represents a main contributor to CO 2 emission to the atmosphere (Lauritzen 2019)Construction materials by weight account for more than 40 % of the resources used in the United States, near 60 % in Japan, Construction and Demolition Waste SpringerLink2021年12月1日 India is a country that primarily depends on coal to satisfy the bulk of its energy as well as electricity needs At the end of 2020, India had around 200 GW of coal based power generation capacity, which was about 53% of the total installed capacity (CEA 2021a, CEA 2021b) whereas for the year 2020, coal was responsible for around 75% of the total electricity Technoeconomic analysis of a 660 MWe supercritical

.jpg)

Exposure to Respirable Particulates and Silica in and around

2010年12月1日 Stone crushing unit workers suffer from particulate matters and respirable silica at work and in their residents nearby The present study was undertaken to evaluate the area and personal exposure 2021年1月1日 Recycling of leadacid batteries starts with breaking, crushing and physical separation into plastic, polypropylene (C 3 H 6) n, sulphuric acid (H 2 SO 4), lead oxide(PbO) and lead oxide/sulphate paste [10]Lead acidbattery recycling market matured and conventional pyrometallurgical process are used to recycle it as represented in the Fig 3 [11]During the Battery recycling opportunity and challenges in IndiaDEWSON is one of the top mobile crusher manufacturers in India, offering highquality mini mobile crushing solutions for various industries +91 988 848 4469 +91 987 200 0995Mobile Crusher Manufacturers in India DEWSON2022年11月1日 1 Introduction The fasttechnological evolutions in the electrical and electronic equipment sector, and their extensive increasing consumption have abruptly enlarged the electronic devices that are either early outdated or discarded, resulting to generation of huge amount of ewaste (Tembhare et al, 2021; Ravi et al 2020, Ravi et al, 2021)In this context, Evaluation of Ewaste materials linked potential

.jpg)

Assessment of Occupational Dust and Silica Exposure in Indian

Materials and Methods A cluster of stone mining and crushing units in the Nalgonda district of Telangana state, India were selected for the purpose of this study Dust monitoring was conducted in four stone mines and their associated crushing units, each having capacities in the range from 100250 TPH, in the month of March 20162020年9月20日 The 2S crushing consisted of primary and secondary crushers as Jaw and HSI (horizontal shaft impactor), respectively, while 3S crushing was composed of primary, secondary and tertiary crushers as (PDF) COMPARISON OF SECONDARY CRUSHING 2019年10月25日 The study uses basaltic aggregate produced from two different crushing mechanisms (i) jaw, cone and VSI (vertical shaft impactor) as primary, secondary and tertiary crushers, respectively (JawConeVSI, denoted as JCV); and (ii) jaw and HSI (horizontal shaft impactor) primary and secondary crushing units, respectively (JawHSI denoted as JH)Understanding Effects of Crushing Mechanism on Aggregate Morphology 2024年10月25日 Only a few varieties are commercially cultivated India is the secondlargest producer of tomatoes, producing 20 million tomatoes every year India contributes to 11% of the world’s total tomato production However, India Tomato processing industry in India ABC Fruits

.jpg)

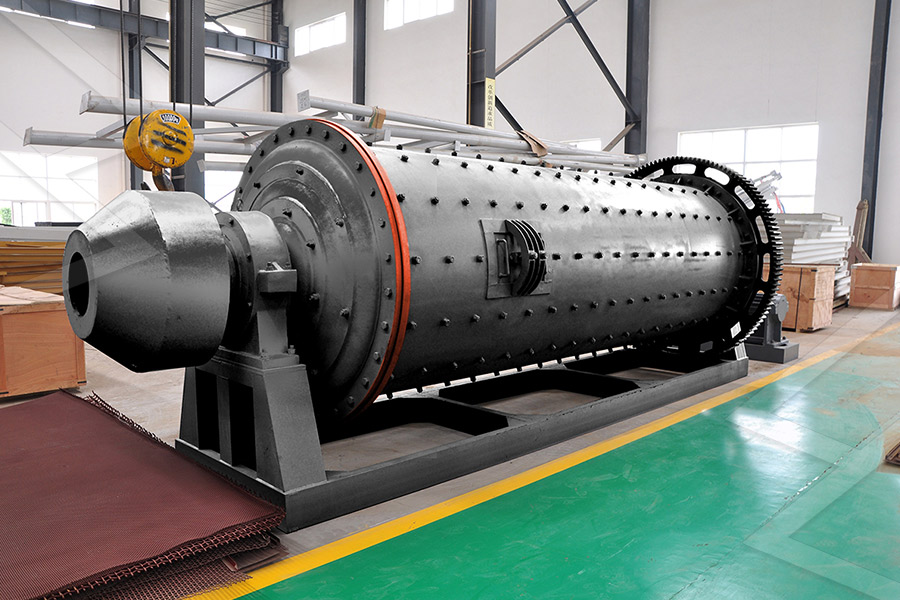

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 10 Introduction: 484,859375 with a total volume of 15,000 tons per month and a unit price of N2,29161/ton while Jolex Construction sells her granite within the prices of N7,500 to N8,000 2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stage2017年4月18日 The quality products manufactured by Tech Makkers is Jaw Crusher, Portable Crushing Unit, Cone Crusher, Vertical Shaft Impactor, Vibrating Screen Tech Makkers offers jaw crushers, which are designed for consistent in performance in all type of heavyduty applications Tech Makkers began as a pioneer brand in the field of crushing EquipmentsJaw Crusher Manufacturer, Jaw Crusher India, Crushing Equipment in India2022年2月18日 The secondary data have also been used in the present study Results: It has been observed that 18% people are engaged with stone carrier work more than 12,000 stone mines and stone crushing units are present in all over India and more than 5 lakhs in the stone crushing unit are suffering from respiratory disease, eyes problem and skin Impacts of Stone Crushing Work on the Tribal Labourers

.jpg)

(PDF) Problems and Prospects of Sugar Industry in India:

This paper is based on both primary data collection and secondary data collection Primary data was collected through field survey which was undertaken to Dhampur Chini Mill, a privately owned mill with the maximum capacity for crushing sugarcane, and Snehroad Najibabad Mill, a cooperative sugar mill with the lowest capacity The sugarcane 2024年10月29日 Secondary crushing – cone crushers Purpose is to prepare feed for grinding circuit, and a tertiary stage is added if necessary (economic decision) Lighter duty than the primary gyratory and jaw crushers Feed characteristics: Maximum feed size is less than 15 cm (about 6 inch) top size Harmful tramp metal, wood, clays and slimes already removed, making Understanding Secondary Crushing in Mineral Processing2023年11月1日 inside the unit and 100m away of the unit were monitored in all the crusher units the concentration of spm were much more than the permissible standard ie, 500 µg/m 3 , where as 100m away the conDust pollution in stone crusher units in anD arounD 2 STONE CRUSHING PROCESS Big size stones are transferred to primary stone crusher through vibrating feeder from hopper for first crushing, and then the crushed materials are transferred to impact crusher through belt conveyor for secondary crushing The crushed materials will be transferred to the vibrating screen, and separated to different Project Report On Stone Crusher Plant Stone crusher plant

Pollution Concerns of Stone Crushing Industry

2022年2月15日 Pollution Concerns of Stone Crushing Industry Prof BK Agarwala Infrastructure sector especially roads, highways and buildings are witnessing high growth in India As a result, several stone crushing units are coming up in several parts of the country which poses many challenges to maintain the National Ambient Air Quality Standards and2020年7月10日 These stages in addition to secondary crushing can often be laid out utilizing an opencircuit portable crusher plant system where processed material is screened and conveyed from one crusher to the next Relying on these many stages of crushing beyond only primary can add great value to a crushing operation Not only can multiple sizes of What Is Primary, Secondary, and Tertiary Crushing?2023年2月28日 Secondary crushers can be classified into different types based on their structure, size, and application Definition and function of secondary crushers Secondary crushers are machines that are used to crush materials after primary crushers They are designed to handle a wide range of materials such as rocks, ores, and mineralsPrimary vs Secondary Crushers: Understanding the 2019年4月28日 cultivation in Indian literature is found during the period 1400 to 1000 BC It is now widely accepted that India is the original home of Saccharum Species India is the second largest producer of sugarcane next to Brazil Production of sugarcane in India is about 339 million tons from an area of 5064 thousand hectare in 2012SUGARCANE SCENARIO IN INDIA A VIEW IJSSER

.jpg)

Primary and Secondary Crushing: Understanding the Basics

2023年2月28日 Secondary Crushing Secondary crushing is the second stage of crushing that takes place after the primary crushing The secondary crusher is the equipment that reduces the size of the materials further, after they have been reduced by the primary crusher The secondary crusher has a size reduction ratio ranging from 3:1 to 5:12023年10月10日 is reported highest in latecrushing period during summer (132 unit d1) followed by midseason crushing during spring (10 unit 02 Optimizing Sugar Recovery in India: Need for an Integrated Approach Citation: MM Roy and Amaresh Chandra “Optimizing Sugar Recovery in India: Need for an Integrated Approach" Acta Scientific Agriculture 43 Optimizing Sugar Recovery in India: Need for an 2019年9月1日 Estimates of Construction and Demolition (CD) waste generation in India range between 150 to 716 million tonnes/ year CD debris recycling, one of the sustainable solutions for managing this CHALLENGES AND PROSPECTS OF DEMOLITION WASTE RECYCLING IN INDIA2024年8月14日 MOBILE CRUSHING UNIT FROM 40 TONS TO 250 TONS PER HOUR FITTED WITH PRIMARY 1 SECONDARY CRUSHERS OR IMPACTORS rsmon READY TO USE CRUSHING STATIONS Unit I : Gat No 581/582, At Post Janori, 10th Mile, Ozar, MumbaiAgra Road, Nashik 422 206 (MS) INDIA Tel: +912557 Unit Il :Plot No 71 2, MOBILE CRUSHING UNIT MODEL MPJ SERIES RANGING