Cement Plant Coal Mill Grinding Flow Sheet Italy

PROCESS OPTIMISATION FOR LOESCHE GRINDING

2017年8月12日 For over 100 years the company Loesche has been building vertical roller grinding mills for grinding: Coal Cement raw material Clinker / granulated slag Industrial 2017年8月11日 The following features are the basis of our competence: Planning and construction of turnkey grinding plants for cement clinker and granulated blast furnace slag 2 µm 5 µm Loesche2016年12月19日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a Reprint from ZKG 3 Gebr Pfeiffer2017年8月12日 Loesche coal grinding mills are distinguished by other characteristics that improve efficiency, safety and environmental protection, from the standard version to topof LOESCHEMILLS

The Cement Plant Operations Handbook International

2019年4月30日 The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel worldwide 2016年11月1日 The paper focusses on improving the energy utilization of a cement grinding circuit by changing the flow sheet of the process The circuit was comprised of ball mill, static Simulation aided flow sheet optimization of a cement grinding The coal mill grinding system is an important part of the dry process cement manufacturing In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is Coal Mill – Coal Mill In Cement Plant AGICO 2018年7月1日 Abstract This study aimed at optimizing both the energy efficiency and the quality of the end product by modifying the existing flowsheet of the cement grinding circuit As a Energy and cement quality optimization of a cement grinding circuit

.jpg)

(PDF) MPS mills for coal grinding ResearchGate

2014年1月1日 PDF Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) Find, read and cite all theGebr Pfeiffer SE supplies standalone MPS coal grinding mills as well as complete coal grindingdrying systems Both mill and grinding system can be operated under pressure or suction as MPS mills for coal grinding Cement Lime Gypsum ZKGThe ATOX® Coal Mill can grind and dry raw coal with up to 25 percent moisture level By adjusting the gas flow stream with the nozzle, you can deal with more ‘sticky’, highmoisture feed materials There is an oversized nozzle ring and ATOX® Coal Mill FLSmidth CementThe ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 05% ~ Coal Mill in Cement Plant Vertical Roller Mill

.jpg)

(PDF) MPS mills for coal grinding ResearchGate

2014年1月1日 The emission factors of kiln end, kiln head, coal mill, crushing and cement mill was 0156 clinker g/t, 3914 clinker g/t, 1538 coal g/t, 0016 stone g/t and 0056 cement g/t respectively, the 5 Jul 2023; A cement plant coal mill grinding flow sheet represents the process of processing coal in the grinding system of a cement plant The flow sheet illustrates the steps that coal and other raw materials undergo during the production of cement It explains the order of various stages of the grinding and drying process, which helps achieve the desired quality and efficiency in Cement plant coal mill grinding flow sheet cmcrusher2017年8月11日 Grinding of cement clinker and granulated blast furnace slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the vertical2 µm 5 µm Loesche2023年12月22日 Cement Plant Operation Handbook Free ebook download as PDF File (pdf), Text File (txt) or read book online for freeCement Plant Operation Handbook PDF Mill (Grinding)

CEMENT PRODUCTION AND QUALITY CONTROL

2019年7月20日 CEMENT PRODUCTION AND QUALITY CONTROL A Cement manufacturing Process Source:civilengineeringforumme The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow 2017年8月12日 Coal Injection) 1990 Central coal grinding plant (LM 263 D) for gas and steam power station (coal gasification) 1992 Central coal grinding plant (LM 263 D) for the production of lignite (brown) coal dust 2002 Coal grinding plant (LM 232 D) for grinding wood pellets for power stations 2005 First 4roller pressure mill (LM 434 D) becomesLOESCHEMILLS2016年12月19日 tion the coal grinding system is operated under inert conditions This can be achieved by using exhaust gases from the kiln preheater in a cement plant Figure 2 shows a general plant layout The coal is fed into the mill through a pressure shockresistant, selfpurifying rotary feeder After being dried, ground and classified in the mill system,Reprint from ZKG 3 Gebr Pfeiffer2024年1月3日 Grinding and separation efficiency of vertical roller mill were evaluated In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were comparedPerformance Evaluation of Vertical Roller Mill in Cement

.jpg)

Coal Mills for Cement Plants Loesche

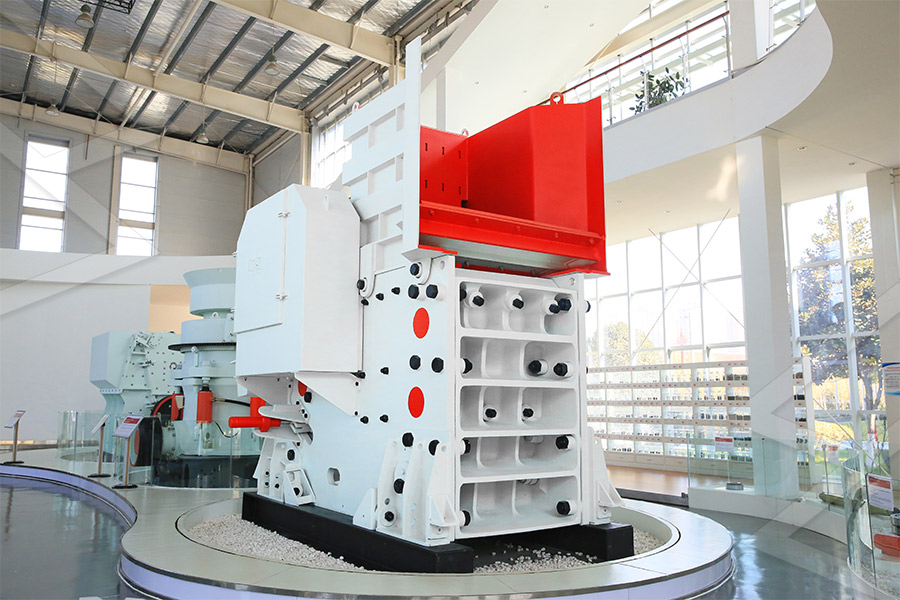

4 天之前 Coal grinding mills LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations Special versions are available with characteristics that meet special safety regulation or output control requirements2018年12月21日 This flow sheet and sampling map shows the process flow for a cement plant Key components include: 1) Raw materials like iron sand, silica sand, limestone, clay and gypsum being fed into crushers and mills 2) Processed materials being fed into kiln systems for heating and clinkering 3) Clinker being stored and transported to other cement plants or customers 4) Flow Sheet Kiln, Raw Mill N Coal Mill PDF Cement Concrete2017年8月12日 biggest coal mill, which successfully went into operation in two cement plants in India in August 2008 Even though this fourroller coal mill was a new development, the required throughput was reached within a few days This type of mill is able to worldcoal Reprinted from March2009 WorldCoal produce up to 120 tph of pulverised coalOFTEN Loesche2021年1月1日 Coal Grinding: Grinding Mill Vertical Roller Mill or Ball Mill: Coal is ground in Coal mill, which is a fuel for use in Kiln firing: 5: Pyro Section, Clikerization: In line calciner six stage preheater Kiln: Cement clinker is made by pyro processing of kiln feed into the preheaterkiln system: 6: Clinker Cooling: Cooler with roller crusherReview on vertical roller mill in cement industry its

.jpg)

Comminution Handbook – Contents AusIMM

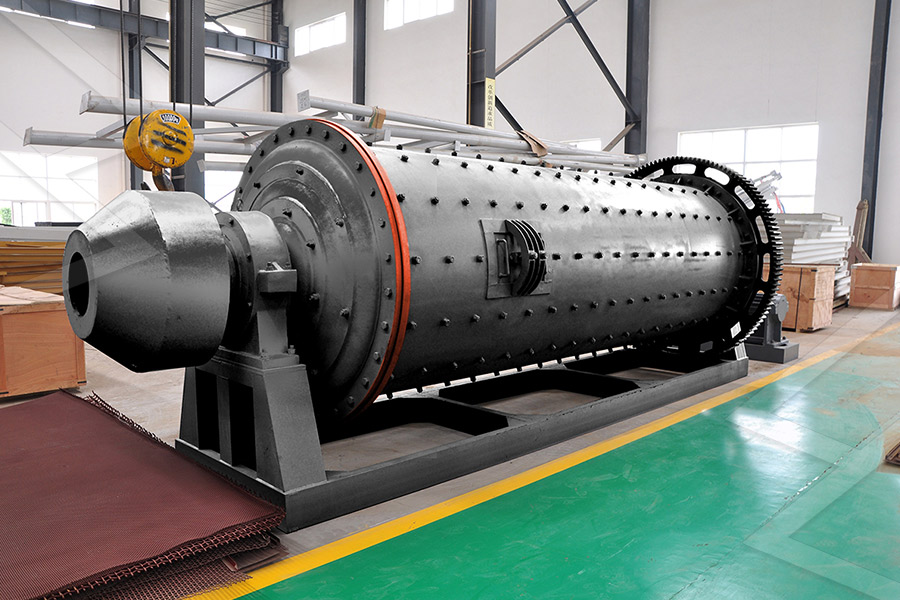

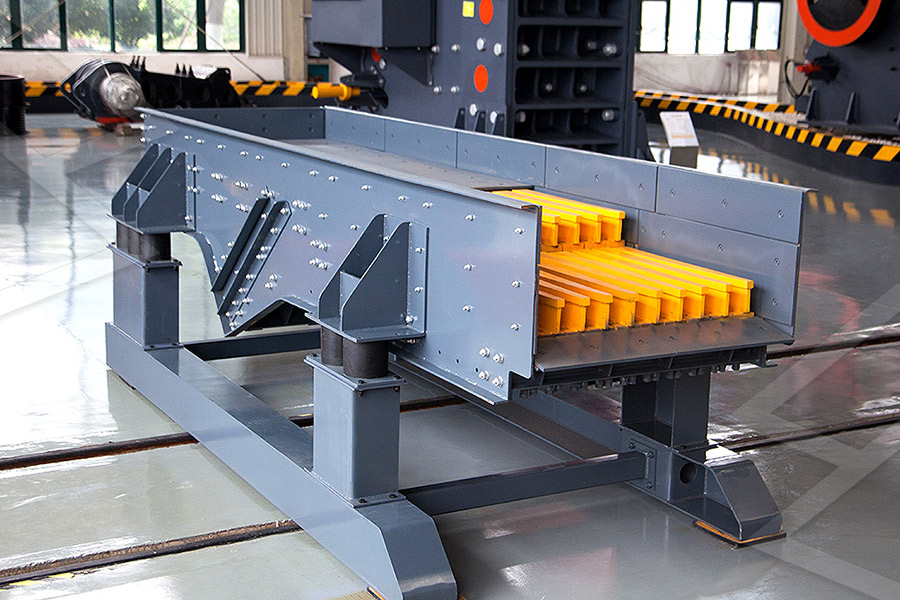

2021年12月21日 Ball mills for cement Ball/tube mills for coal Ball mills for ores Autogenous/semiautogenous grinding mills Rod mills Rotary breakers for coal Scrubbers Grinding balls Building large tumbling mills Flow sheet options Comminution energy calculations Equipment sizing and selection2023年12月23日 The coal mill fan is usually installed on the top of the coal mill, and its inlet is connected to the coal mill discharge port, and its outlet is connected to the furnace The coal mill fan is driven by a motor, and the motor drives the fan impeller to rotate, which generates centrifugal force to suck in air from the inlet and blow it out from Centrifugal Fans in Cement Industry: Crucial Roles TechflowGulin Least News coal plant operations coal production flow sheet » The More » dantin 20 x 30 jaw crusher » is basalt non metal or metal » shenzhen glede machine equipment limited » sand blasting machine for glass ebay » metal detector for alluvial gold in ghana Contact Us Tel: 8621; Office Add: Pudong New Area, Shanghai, Chinacoal plant operations coal production flow sheet – Grinding Mill A simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Coal Mill an overview ScienceDirect Topics

Vertical Grinding Mill (Coal Pulverizer) Explained saVRee

Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millAdjusting mill parameters: Finetuning mill parameters such as mill speed, ball charge, filling ratio, and grinding media size can have a substantial impact on the grinding efficiency of the mill For example, a 10% increase in mill speed can result in up to 10% higher production rate, while optimizing the ball charge can lead to a 510% Cement Mill Optimization: Practical Strategies for Enhanced 2021年7月14日 met coal preperation plant flow sheet – Grinding Mill China Posted at: August 8, 2012 Head : Mr T Gouricharan Coal Washing Pilot Plant Fine Coal Treatment Development of flow sheet for beneficiation of » Free online chat! cement plant coal mill grinding flow sheet Clinker Grinding Unit – Cement Plant ¤ Flow Chart Diagram Ball Mill: 3Gypsum Hopper: 7coal flow sheet washing plant – Grinding Mill ChinaAirswept coal mill is the main equipment of cement plant, also called coal mill in cement plant, used for grinding and drying various hardness of coal, crushing the coal briquette into pulverized coalIt is the important auxiliary equipment of Coal Mill In Cement Plant, Airswept Coal Mill

Three Stage Flow Sheet with Two Stage HPGR

Also, equipment like ball mill is used at the final stages of grinding Among the comminution and grinding equipment, HPGR is increasingly utilized as tertiary crusher or primary mill because of In addition to the vertical slag mill, other types of cement mill that can grind slag powder include: cement ball mill, pregrinding cement roller press, and cement roller press for final grinding For slag grinding plant, ball mill generally causes problems of dust accumulation, low grinding efficiency and high grinding temperature The Slag Grinding Plant GGBS Plant Slag Mill, Slag Cement PlantBall mills for cement raw material and coal equipped with a drying compartment adequately air swept with hot gas (2535M/sec above the ball charge), can handle moisture about 8% Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a Raw Material DryingGrinding Cement Plant Optimization2024年3月15日 This document discusses optimizing cement separator and ball mill systems through periodic testing and evaluation It provides guidance on when and why to conduct optimization, including abnormal operations, poor performance, or high costs Conventional grinding systems and their main components are described The document then covers ball Cement Separator Ball Mill Optimization PDF Mill (Grinding

EnergyEfficient Technologies in Cement Grinding

2016年10月5日 1 Introduction Cement is an energyintensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost []The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns In recent years, the production 2021年7月14日 Process flow sheets: Production Process of Mini Jun 20, 2011 Raw Materials The major raw materials required for the production of cement are limestone, clay, sandstone, gypsum and pumice The dry process of cement » Free online chat!process flow sheets of a cement plant dry process Grinding Mill InBuilt Reliability for Cement Plant Application: Raw Material, Cement, Slag, Coal and Minerals In May 2019, AMCL signed an exclusive Licensing Agreement for the design, manufacture, erection, commissioning and after sales service with UBE Machinery Corporation, Ltd (UBE) of VRMs in India, Bangladesh and NepalVRM – AMCL Machinery Limited2016年1月20日 In the surveyed cement plant, three balances are established between input and output material in the raw mill, clinker production, and cement grinding system 248 t, 469 t, and 341 t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages; waste gases account for Analysis of material flow and consumption in cement production

.jpg)

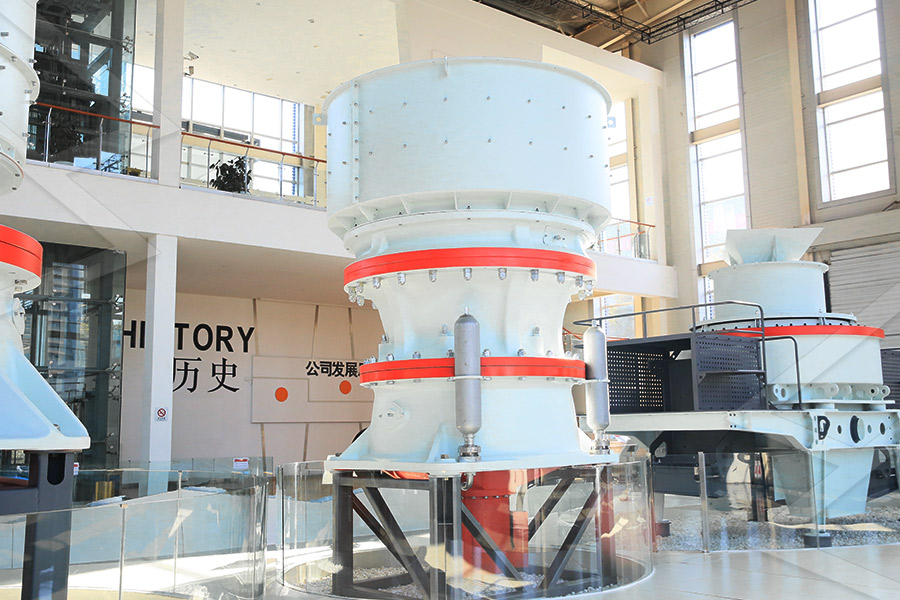

quadropol® thyssenkrupp Polysius Grinding

The installed 4,000 tons kiln line at Afyon Cimento is successfully in operation for many years, showing truly equipment reliability and stable plant performance For raw material grinding a quadropol® vertical roller mills QMR² 45/23 was 2023年1月1日 The utilization of coal in the cement and concrete industries takes three basic forms: (1) as a fuel in the production of cement clinker; (2) ash produced by burning coal in power stations is used as a component in cement rotary kiln feeds; (3) ash produced by burning coal in power stations is used as a mineral additive in concrete mixesCoal utilization in the cement and concrete industriesOn the one hand, it reduces the particle size of materials before the formal grinding, on the other hand, it causes the cracks and defects inside the particles to greatly improve the output and reduce the energy consumption of the cement grinding mill Cement grinding process mainly includes the mixed materials crushing, material batching, pre Cement Grinding Unit Clinker Grinder AGICO Cement2024年3月16日 Cement grindingFlow sheet Free download as PDF File (pdf), Text File (txt) or view presentation slides online This document appears to be an engineering drawing or specification sheet, as it includes fields for the person who drew it, approval date, material, weight, welds, international standards, scale, drawing number and version numberCement Grinding Flow Sheet PDF Scribd

Thomas Holzinger, Holzinger Consulting, grinding

2021年3月12日 Comparison of cement grinding systems for ordinary portland cement at 3500 Blaine, 4% limestone Ball mill Combi grinding system Finish grinding Ball mill with cage rotor separator Roller press in semifinish mode and ball mill VRM Roller press Specel Energy consumption mill motors kWh/t 30 25 17 17 % at mill motor (ball mill 100%) % 100 83 57 年3月12日 The key features of a coal grinding plant in a cement works are: special layout of the plant to avoid coal dust deposits; pressureshock resistant design of mill and classifier housing, filter and pulverized coal silos; flow rate the mill control range is between 30 and 100% Partload operation may become necessary as a result of load MPS mills for coal grinding AYS Engineering2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and 2024年3月15日 1 cement mill ppt Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses cement grinding systems It describes open circuit mills which have multiple compartments for coarse and fine grinding Closed circuit mills typically have two compartments and a separator to return 1 Cement Mill PDF Mill (Grinding) Scribd

R)8OC`6F[ZIB.jpg)

Cement Plant, Cement Equipment Cement Plant

Cement plant is necessary for cement production, and mainly consists of a series of cement equipment apply for the preparation of cement raw materials, clinker production, and finished cement production, such as a cement mill, cement crusher, rotary kiln, cement roller press, cement dryer, clinker cooler, cement silo, and related cement plant equipment