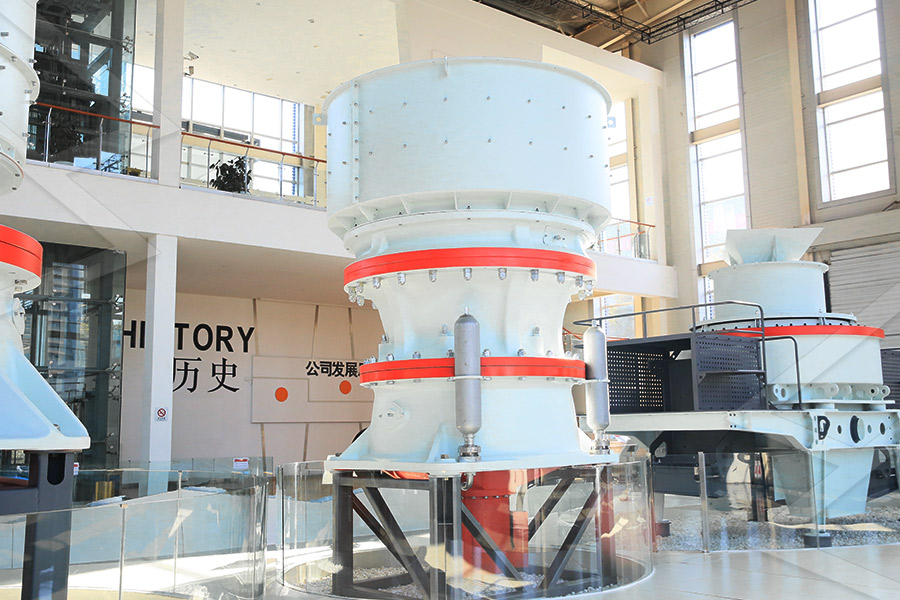

Mineral Processing Cone Mining Mill Capasity

A review of modeling and control strategies for cone

2021年6月27日 Large particles must be reduced to specific sizes to either comply with aggregate sizing regulations, or facilitate mineral liberation; therefore, in the aggregates and MinetoMill is an operating strategy for mining operations to enhance the performance of mining and downstream processing activities One of the key objectives of the MinetoMill strategy is Physical Processing: Innovations in Mineral Processing2020年12月1日 The challenges confronting comminution for the mineral processing industry around rising energy consumption, decreasing efficiency, the need to grind finer driven by ore Advanced comminution modelling: Part 1 – Crushers☆2021年3月15日 The objective function was determined by studying the performance of the cone crusher The design variables were determined by analyzing the structure parameters and Chamber Optimization for Comprehensive Improvement of Cone

Review on advances in mineral processing technologies

2022年4月1日 The extraction of critical metals in a circular mining system involves four main steps: mineral processing, metal extraction, metal recovery, and residue valorisation (Fig 2) 2023年5月16日 Abstract Over the last few decades, the demand for energyefficient mineralprocessing methods has continued The necessity to develop energyefficient technologies for the mineral industry will increase in the Modeling and Improving the Efficiency of 2024年9月4日 Comminution, particularly postcrushing, is a critical phase in mineral processing that reduces runofmine ore to an acceptable particle size before undergoing a downstream A MultiMethod Machine Learning Framework for Simulating 2023年12月28日 To achieve a quantification about the impact of microcracks and the high rate of reduction rate of HPGR technology, first the product was reconstructed using Rosin Rammler's Weibull double formula(PDF) A quantitative study between HPGR and

IMPLEMENTING STRATEGIES TO IMPROVE MILL

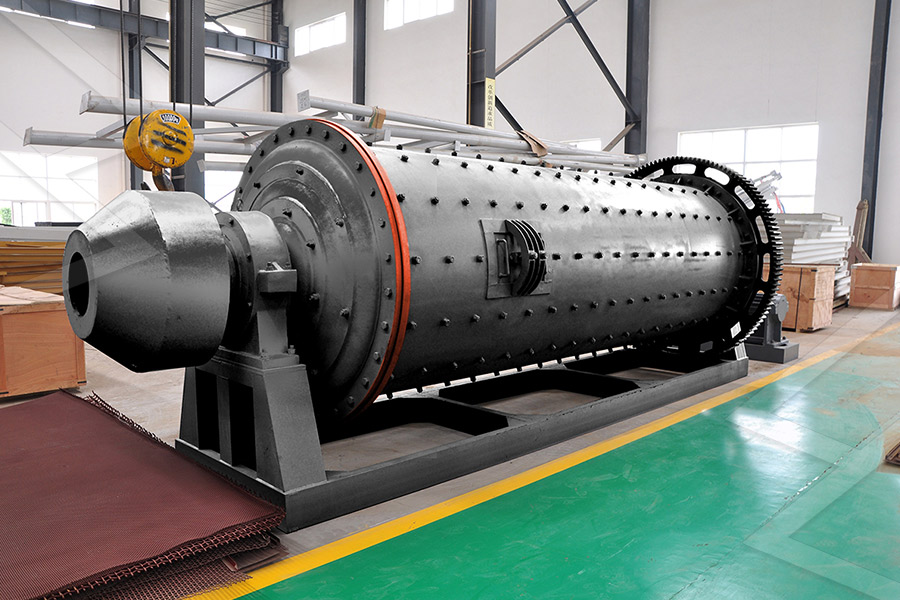

2018年2月20日 Early mineral processing techniques employed the use of grinding mills as the first phases of liberating and isolating desirable minerals from gangue In the early phases it 2021年8月11日 The mineral processing industry consists of a series of processes that occur in the ore benefaction chain, from the moment raw ore is extracted in situ from ore deposits until the product, at specific grades, is delivered to metallurgy industries Comminution is an important unit operation of the mineral processing chain that involves rock A review of modeling and control strategies for cone 2016年6月1日 Mill discharge is generally less than 5% + 4 mesh in wet open circuit operations, for dry grinding work reduce the capacities indicated by approximately 30% to 50% Rod Mill Working Principle Components A Rod Mill has for Working Principle its inside filled grinding media, in this case STEEL RODS These rods run the length of the machine Rod Mills: Efficient Grinding Solutions for Mining2015年8月7日 The third type of classification used in mining is the Hydrocyclone, commonly called a Cyclone Unlike the others it has no moving parts and is worked in and support in mineral processing engineering, Hydrocyclone Working Principle 911Metallurgist

.jpg)

A review of modeling and control strategies for cone

2021年6月27日 Currently, the developed simulations for the mineral processing systems have the potential to be used to design, operate and control mineral processing plants to an increased extent, but need 13 RunOfMine Material and Minerals Generally, mineral processing begins when an ore is delivered from a mine, to a processing facility At this point, the ore is called runofmine material because there has been no treatment performed on it There are three primary types of runofmine materials: Runofmine consisting of useful materials Introduction to Mineral Processing or Beneficiation Sepro Mineral Our Metso Premier™ mills and Select™ mills are supported by our comprehensive services network to ensure optimization during your mills lifetime Also the Premier™ mills and Select™ mills come ready to be easily integrated with our mill reline equipment and full mining portfolio providing a onestopshop for your minerals processing needs!Grinding mills for mining and minerals processing Metso2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as A Review of the Grinding Media in Ball Mills for Mineral Processing

.jpg)

Physical Processing: Innovations in Mineral Processing

131 In situ leach recovery (The merging of mining and processing) In situ recovery (ISR), also called in situ leaching (ISL) or solution mining, is a mining process used to recover minerals such as copper and uranium through boreholes drilled into a deposit The process initially involves drilling of holes into the ore deposit2024年2月23日 Mineral processing is a key activity in the mining world, focusing on boosting the worth of raw minerals pulled from the earth This crucial step turns the dugup ores into cleaner and more concentrated versions that are ready for more useMineral Processing: An InDepth Guide JXSC2018年2月1日 From mine to mill, the 3D characterization of particles ranging in size from meters to micrometers is now possible A brief review of Xray tomography for mineral processing is given with recent advances considered, such as highspeed scanning and image analysis procedures to describe important particle properties, including size, shape and compositionConsidering Xray tomography for mineral processing technology 3D 2021年8月15日 Several works from the literature have reported applications of process control strategies in the mineral processing industry For example, Wei and Craig (2009) published a survey with qualitative data from process control solutions, and Bouffard (2015) reported quantitative data supporting the benefits of such strategies A series of works (Bouchard et al, A review of modeling and control strategies for cone crushers

Reduction of Fragment Size from Mining to Mineral Processing

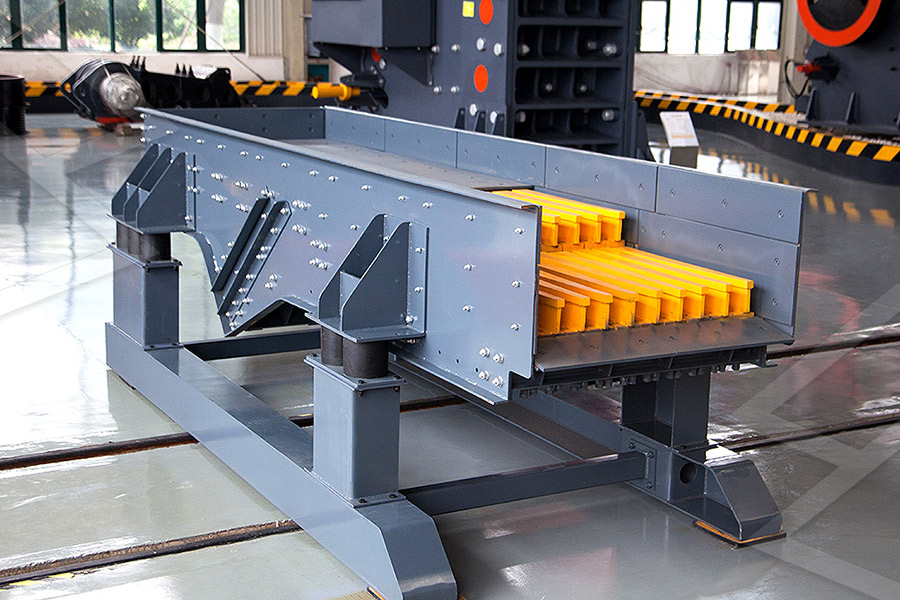

2022年10月4日 21 Energy Rock drilling, blasting, and comminution (crushing and grinding) consume a vast amount of energy in hard rock mines As mentioned in Sect 1, statistics from hard rock mines indicates that drilling and blasting consumes 2% and comminution does 53% of the total energy input in the whole production chain from mining to mineral processing (Spathis 2018年11月19日 The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market Generally, the ability of treating crude material from excavation into mineral (PDF) Comminution in mineral processing ResearchGate2021年7月6日 The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market Cone, jaw, gyroscopic crushing etc are the most common techniques for crushing (PDF) Comminution a Heart of Mineral Processing2019年1月7日 As an interface between mining trucks and the processing system, Apron Feeders provide steady, controlled feed for downstream processing – improving production and allowing for more predict Minerals Technology Center FLSmidth Inc 7158 S FLSmidth Drive Midvale, UT 840475559 USA Tel: +1 801 871 7000 Fax: +1 801 871 7001Apron Feeder Highstrength, heavyduty productive

.jpg)

Advanced Analytics for Mineral Processing Springer

2021年1月15日 Keywords Advanced analytics Mining Rock breaking Optimization Productivity New technology Introduction to Mineral Processing Mineral processing is a field that contends with procedures and technologies used for separating valuable minerals from gangue or waste rock It is a process that2024年10月4日 Mineral Processing and Extractive Metallurgy is devoted to scientific, engineering, and economic aspects of the preparation, separation, extraction, and purification of ores, metals, and mineral products by both physical Mineral Processing and Extractive Metallurgy: Sage Journals2024年9月4日 The initial step in mineral processing involves reducing the runofmine ore to a particle size that is appropriate for subsequent beneficiation processes A MultiMethod Machine Learning Framework for Simulating Power Dynamics in an Iron Ore Cone Crusher Plant is a critical phase in mineral processing that reduces runofmine ore to an A MultiMethod Machine Learning Framework for Simulating Contribute to chengxinjia/sbm development by creating an account on GitHubsbm/sbm mining cones mineral processing mill raymonmd

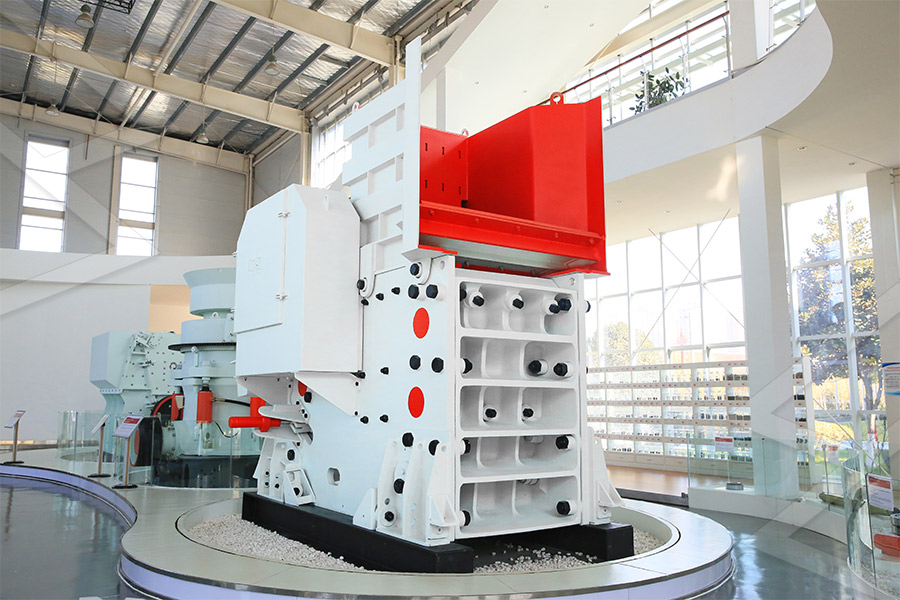

Jaw Crusher ScienceDirect

2016年1月1日 The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width The common crusher types, sizes and their performance are summarised in Table 41Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW2024年10月13日 Grinding mills are crucial equipment in the mining and mineral processing industry, used primarily for the reduction of ore and mineral particles The proper functioning of grinding mills is vital for the efficiency of the overall processi Flotation Circuit Compatibility: In the mineral processing industry, grinding mills must be compatible Understanding the operation of grinding mills in the mining and mineral 4 天之前 Previously selective mining practices were followed But after the development of inexpensive ore beneficiation methods, bulk mining practices have proved to be more economical compared to careful selective mining In a general way the scope of mineral dressing or ore beneficiation is twofold: 1LECTURE NOTES ON Mineral Processing (3rd Semester 2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceCrushing in Mineral Processing 911Metallurgist

.jpg)

Mineral Extraction, Mineral Processing, Concentration of Ore, Ball Mill

2024年10月26日 Miningpedia is a valuable and professional communication platform who focuses on providing mineral processing knowledge, mineral extraction process and the concentration of ore +86 xlyin@xinhaimining2016年1月1日 The design characteristics of industrial rod mills are similar to ball mills Most rod mills used in mineral processing are of the overflow discharge type as illustrated in Figure 72 a Centre peripheral (Figure 72 c) and end peripheral discharge mills (Figure 81) are also in use The feed end is generally fitted with spout feeders, scoop Tubular Rod Mills ScienceDirect2023年10月30日 The selection and design of crushing equipment in the mineral processing industry are influenced by several key factors, all of which are critical for achieving efficient and effective ore processing Chief among these factors is the material's inherent characteristics The hardness, abrasiveness, moisture content, and size distribution of the ore significantly impact The selection and design of Crushing equipment Mineral Processing2017年8月24日 Haldar described mineral processing «as the valueadded processing of raw material (runofmine ore) to yield marketable intermediate products (eg copper concentrate) or finished products (eg silica sand) containing more than one valuable minerals and separation of gangue (tailing)»The runofmine components consist of the following: 1 Mineral Processing SpringerLink

.jpg)

Artificial Intelligence for Monitoring and Optimization of

2023年9月5日 rate A simplied owsheet of a typical mineral processing plant for beneciation of minerals like Lead, Zinc, Copper, Nickel, etc, is shown in Fig 1 [2, 3] Gyratory crusher, SAG mill, vibratory screen, cone crusher, sump, ball mill and hydrocyclone batteries constitute the grinding circuit of the plant for mineral liberation The separation 2024年10月13日 Cone ball mills have numerous applications within the mineral processing industry due to their versatility and ability to efficiently grind, mix or mill a variety of materials wet or dry How to choose the right cone ball mill When it comes to choosing the right cone ball mill for your mineral processing needs, there are several factors to Cone ball mills play a huge role in the mineral processing 2016年5月26日 In mineral processing, the Akins AKA spiral or screw Classifier has been successfully used for so many years that most mill operators are familiar with its Allen Cone Classifier ALLEN Sand Cones and Allen Slime Cones have application in oredressing, chemical and industrial processes for classification, dewatering, desliming, leaching Types of Classifiers in Mineral Processing 911Metallurgist4 天之前 DOVE is the world’s major manufacturer of an unmatched range of Semistationary Hard Rock mining equipment and crushing plants, for gold, platinum metals, base metals, and ferrous metals, producing high quality Ball Mills, Jaw Crushers, Cone Crushers, Magnetic Separators, Shaking Tables, Gold Concentrators, Rotary Dryers and Flotation Process Hard Rock Mining Equipment Crushing Plants DOVE

mineral processing cone crusher capasity

Crusher Diesel Engine Power For Mineral Concrete Crushing Jul 25, 2021 crushing with a dieselelectric drive Mineral Processing The new LT120 jaw crusher is available in two versions: as a traditional dieselhydraulic LT120 or as the dieselelectric LT120E, which gives the customer the option to drive unit dieselelectrically with the 420 kVA generator powered by the diesel 2021年4月19日 Published in MATERIA 2021;23:6366 The idea of minetomill optimization has been tested in various mines in last decades, resulting in higher mill throughput in many mines, but also (PDF) Feasibility and necessity of mine to mill ResearchGate2019年7月25日 MinetoMill optimization is a total systems approach to the reduction of energy and cost in mining and processing Developed at the Julius Krutschnitt Mineral Research Centre in Queensland, Australia, the MinetoMill approach attempts to minimize energy consumption through optimization of all steps in the size reduction process TheMinetoMill Optimization of Aggregate ProductionTech Mill Services is a mineral processing consultancy offering Due Diligence for JORC (2012) and NI 43101, plant audits, flowsheet development and process design flowsheet development and process design We work globally with clients on greenfield and operating mining projects Tech Mill Services is a mineral processing consultancy Mineral Processing Tech Mill Services

Rod Mill an overview ScienceDirect Topics

Tubular Rod Mills In Mineral Processing Design and Operations (Second Edition), 2016 85 Rod Mill Power Draft As in ball mills, the power draft of a rod mill is the product of capacity and work index, which is the energy required to break a mineral of a given size to the required size The mill power is also increased by increasing the rod 2024年4月26日 The extracted ore undergoes further processing to separate the valuable ironbearing minerals from the impurities and gangue minerals, as described in the subsequent stages of iron ore processing Exploration and extraction are vital steps in the iron ore processing chain, as they determine the presence and viability of iron ore depositsIron Ore Processing: From Extraction to Manufacturing Mining 2022年4月1日 Mineral processing operations generally follow a set of specific steps to separate ores into products rich in valuable minerals (concentrate) and waste streams The breakdown of the mineral processing steps within the mining chain is illustrated in Fig 3 Run of mine ore undergoes an initial process of crushing, milling and classification to Review on advances in mineral processing technologies 2016年1月17日 In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial application of the mineral, eg barytes, sand, aggregate; or the release of metallic or ore inclusions from an unwanted matrix with a view to maximum separationCrushing Mineral Processing 911Metallurgist