With Increasing Grade Iron Ore Screening

.jpg)

The impact of new technologies on the iron ore

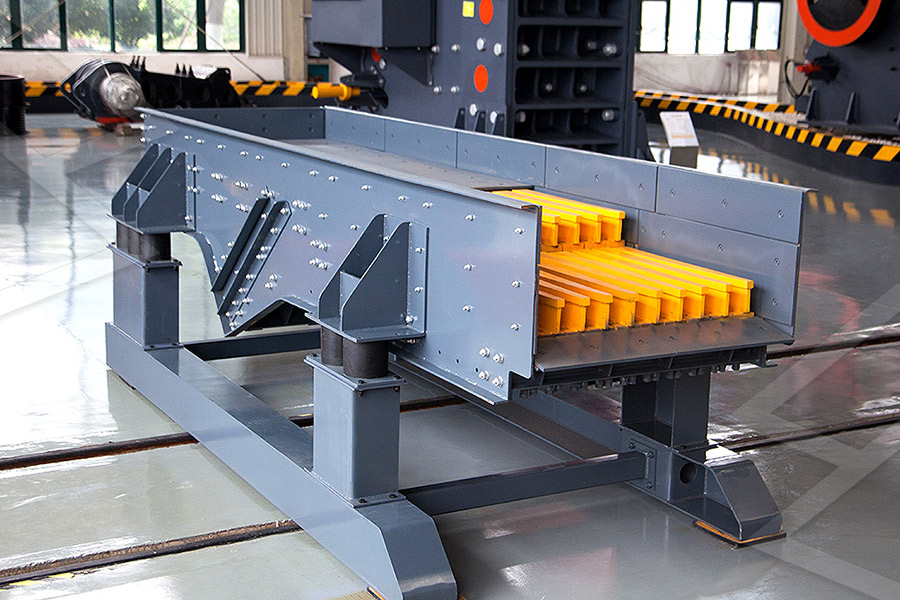

The iron ore pellet holds a pivotal role in the ironmaking process, enabling the utilization of highgrade ore and the upgrading of lowgrade deposits [1] This process involves several steps, including fragmentation, size separation, concentration, and dewatering to rene the ore2024年4月19日 The paper offers insights into significantly improving the screening efficiency of iron ore pelletizing plants by comparing the performance of the operational unit using a The impact of new technologies on the iron ore screening 2022年1月1日 Most of the highgrade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct Comminution and classification technologies of iron ore2024年4月19日 The iron ore screening process plays a pivotal role in determining the dimensions of pellets that enter the firing process of a pelletizing plant The particle size distributionThe impact of new technologies on the iron ore

.jpg)

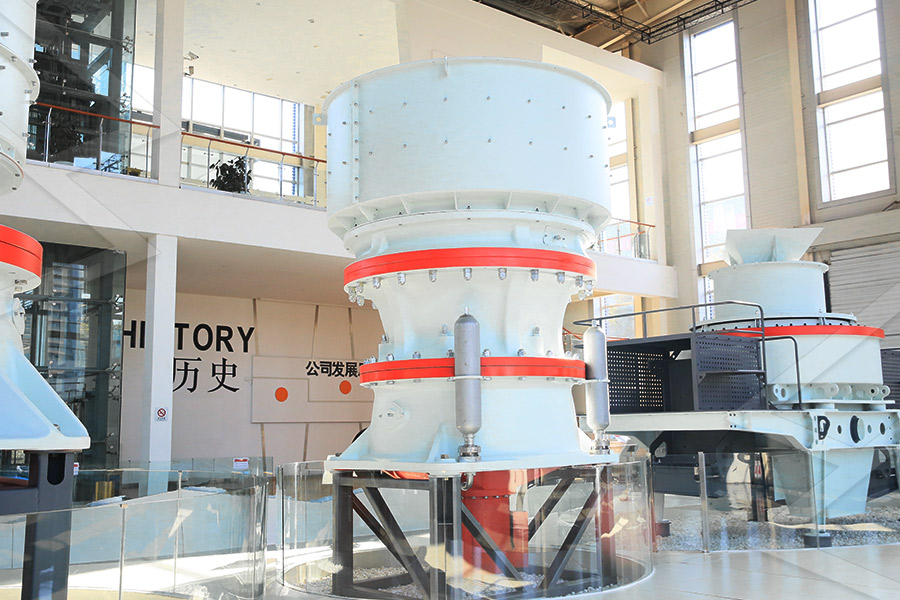

Impact of key parameters on the iron ore pellets roller screening

2022年3月18日 This paper has the objective to fulfill this deficiency by bringing practical and literature review understandings Some parameters directly related to the screening ratio 2019年11月30日 The surface mine planning and optimisation techniques such as block modelling, pit optimisation, scheduling, stockpiling and reconciliation that are and have been Mine Planning and Optimisation Techniques Applied in an Iron Ore 2023年8月1日 In the recent past, iron ore resources from Brazil consisted of relatively highgrade iron ore, commonly processed via multistage crushing/screening, gravimetric Transforming iron ore processing – Simplifying the 2024年4月18日 This review delves into recent biobeneciation advancements for enhanced lowgrade iron ore recovery using microbes Research has revealed that biobeneciation methods Towards a Sustainable and Enhanced Iron Ore Recovery:

.jpg)

Iron ore beneficiation: an overview ScienceDirect

2023年1月1日 The beneficiation plant is designed to process less than 10 mm of lowgrade iron ore fines Lowgrade fines fed to the plant are scrubbed and then classified into two size 2024年3月16日 Biobeneficiation presents a longterm, environmentally friendly, and sustainable alternative to traditional iron ore processing methods Bioleaching, bioflotation, and bio Towards a Sustainable and Enhanced Iron Ore Recovery: Bio Iron Ore Screening Multotec Iron ore screening equipment from Multotec is made from polyurethane or rubber screening mediaOur screening equipment is ideal for high, medium or low grade profiles, reduce plant footprint by more than 33% and materials of construction ensure a long life at reduced cost with low maintenance requirementswith increasing grade iron ore screening2022年1月1日 Due to the depleting reserves of DSO ores and increasing development of lowgrade hematite and magnetite deposits, the need for iron ore comminution and beneficiation is increasing Even the DSO ores are requiring a higher level of processing as mining operations are extended below the water table where ores are wet and more sticky which Comminution and classification technologies of iron ore

.jpg)

Characterization and Beneficiation of Dry Iron Ore

2018年9月18日 Iron ore is the basic raw material for iron and steel making India is among the leading producers of iron ore in the world and produces about 150 million tons per annum (U S [])The total reserves of iron ore in India is around 285 billion tons, of this hematite ore is considered to be the most important iron ore because of its high grade quality and lumpy nature2024年4月18日 iron ore recovery while tackling the constraints of dwindling highgrade iron ore resources and environmental sustainability screening, washing, magnetic separation, and further concentration using froth otation or leaching [10] Rising costs and increasing regulations threaten the longterm viability of these traditional processesTowards a Sustainable and Enhanced Iron Ore Recovery: 2022年1月1日 Turning to iron ore exports and imports, the tonnages are summarized in Table 11 for 2012 and 2018 (Australian Department of Industry, Science, Energy and Resources, 2021; US Geological Survey, 2020; United National Conference on Trade and Development (UNCTAD), 2021)As shown in Fig 13, China is the largest iron ore importing country and imported about Introduction: Overview of the global iron ore industry2024年4月19日 The iron ore screening process plays a pivotal role in determining the dimensions of pellets that enter the fi ring process of a pelletizing plant The particle size distribution res ulting from The impact of new technologies on the iron ore screening

.jpg)

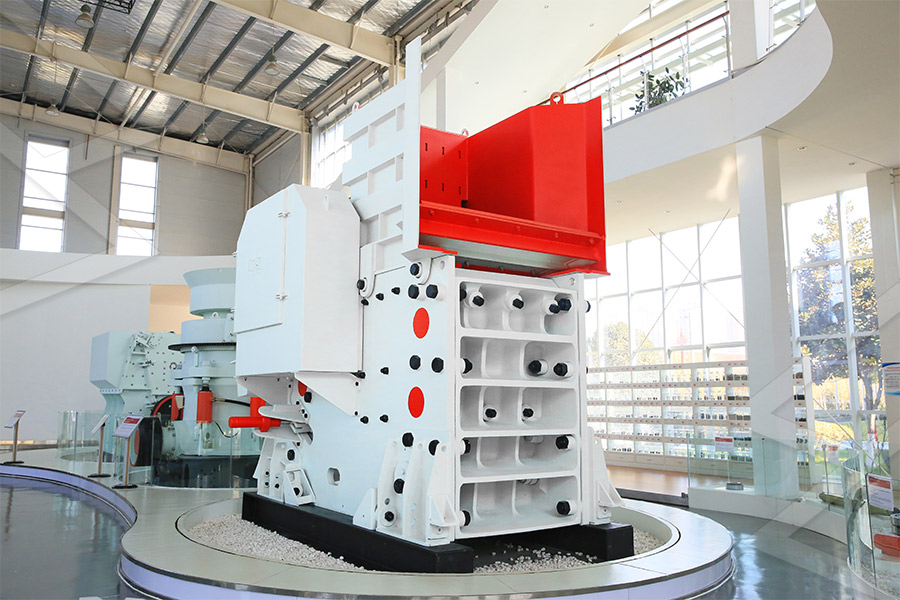

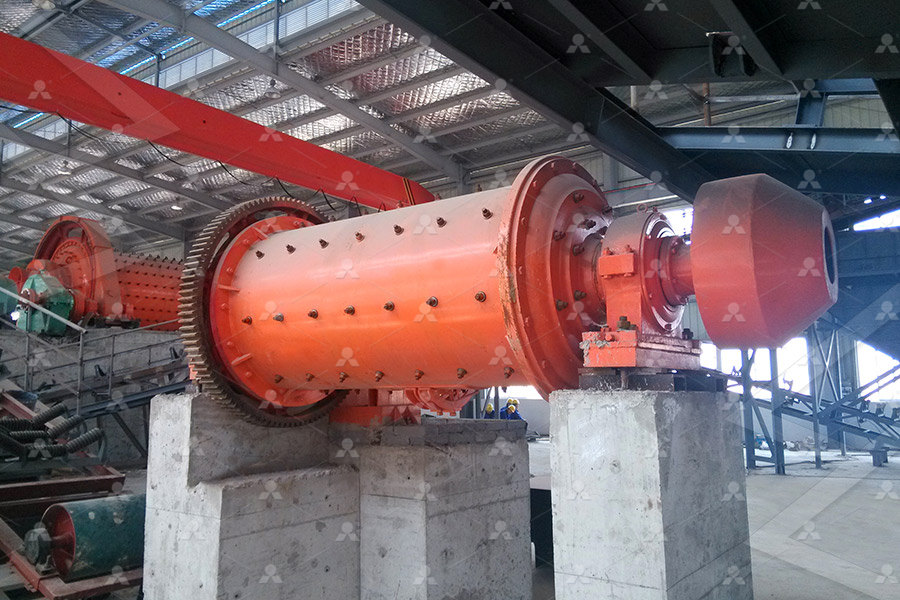

Beneficiation Plants and Pelletizing Plants for Utilizing

2015年1月27日 has resulted in a large increase in the demand for iron ore The quality of iron ore deposits, however, has deteriorated worldwide as a result of longterm mining, and the existing mines are having increasing difficulty in producing ore with a high grade of iron by simple screening Currently, blast furnaces are mainly used for ironmaking2024年4月26日 d Resource Evaluation: Based on the data collected from remote sensing, geological mapping, and drilling, geologists estimate the size, grade, and economic viability of the iron ore deposit This evaluation helps determine whether further development is warranted 2 Extraction After identifying a viable iron ore deposit, the extraction Iron Ore Processing: From Extraction to Manufacturing3 Screening machines for iron ore and coal The crushing and screening systems for iron ore processing vary widely, depending on whether a magnetite or hematite deposit is being mined While good quality magnetite is now dryprocessed, hematite from deposits below the water line requires wet processing due to sticky quartz and clay contaminationsAdvances in screening technology in the mining sector2018年12月19日 ores because of depletion of highgrade iron ore The lowgrade ores are highly contaminated with alumina — 7 to 8 percent — and silica — 8 to 9 percent — and demand new beneficiation techniques to make them usable The advantage of wet washing circuits is limited to the partial removal of adhering alumina and silica in the iron oreDevelopment of process for beneficiation of lowgrade

CURRENT PRACTICES IN INDIAN IRON ORE

2024年3月7日 Most of the iron ore mines in India have been operated by selective mining for maintaining highgrade of ore 2 Tomaintain highgrade ore, lowgrade lumps and laterite are rejected2023年1月1日 The quality of Indian iron ore resources is generally good with high iron content and high percentage of lumpy ore More than 85% of the hematite ore reserves are of medium to highgrade (+62% Fe) and are directly used in blast furnace and in directreduced iron (DRI) plants in the form of sized lump ore, agglomerated sinter, and agglomerated pellets (Iron and Iron ore beneficiation: an overview ScienceDirectContribute to dinglei2022/en development by creating an account on GitHuben/114/second grade iron ore after screeningmd at main2020年4月15日 Currently, the most used iron ore beneficiation techniques are gravity, magnetic separation, screening, crushing, and spiral concentration, as outlined in Fig 2A review on the enrichment of iron values of lowgrade Iron ore

Ore Beneficiation an overview ScienceDirect Topics

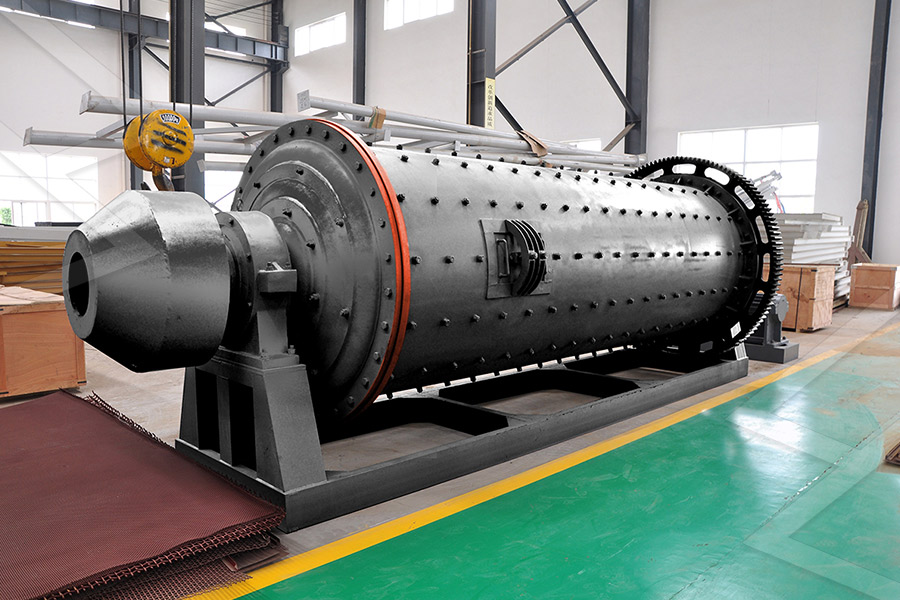

Life cycle assessment of iron ore mining and processing N Haque, T Norgate, in Iron Ore, 2015 2025 Screening and separations Screening is an important step for dry beneficiation of iron ore Crushing and screening is typically the first step of iron ore beneficiation processes In most ores, including iron ore, valuable minerals are 2016年1月28日 iron ore is expected to rise by more than 200 million tonne per year to meet the internal demand export This additional requirement of iron ore will need beneficiation of low grade ore/fines to get the major portion of increased demand This paper deals in brief to use of available methodologies for beneficiation of iron ore in Indian contextAdvances in Low Grade Iron Ore Beneficiation MECON2023年8月1日 Much of the remaining iron ore resources in Brazil consist of lowgrade itabirite ores Accordingly, a typical beneficiation circuit includes a fourstaged crushing/screening plant, followed by grinding in a closedcircuit ball mill, desliming in hydrocyclones and final ore mineral concentration via multistage reverse flotation and thickening of the final productTransforming iron ore processing – Simplifying the While higher prices can be obtained for highgrade iron ore, the extraction of lowgrade iron ore is becoming increasingly uneconomic owing to falling prices high level acceleration that contribute to prevent clogging of the screen media by the sticky and extremely abrasive ore As screening surfaces, special PU hybrid materials are used Dry beneficiation of iron ore Mineral Processing

.jpg)

Reduction Roasting Followed by Pelletization Study of

2024年4月22日 Utilizing iron ore mining wastes like dump fines, slimes, and tailings, which contain significant iron values, is essential to meet future needs and environmental sustainability, requiring intensive research to develop a process that can identify the route for sustainable usage Reduction roasting is a proven route for converting and recovering highgrade iron value from 2022年3月18日 1 Metal 7 Inc, 285, des Pionniers, CP 1590, G4R 4X9, SeptÎles, QC, Canada 2 Minerai de Fer du Québec, 1100, Boul RenéLévesque Ouest, Suite 610, Montréal, QC H3B 4N4, Canada * email: agandrade@metal7 Received: 18 March 2022 Accepted: 5 May 2022 Abstract The roller screening process is an important step in the iron ore pellets productionImpact of key parameters on the iron ore pellets roller screening 2019年11月30日 The 50 m × 50 m grid assisted in increasing the level of confidence and the definition of the orebody was clearer, therefore allowing for geological block models which categorizes resources into measured, indicated and inferred to be created ON grade ore processing is only crushing and screening OFF grade ore is taken through crushing Mine Planning and Optimisation Techniques Applied in an Iron Ore 2022年12月1日 It can be found that 82 wt% of the iron ore concentrate is composed of magnetite and 11 wt% of hematite, while SiO 2, MgO, CaO, and Al 2 O 3 are present as the main gangues in iron ore concentrate Total Fe agrees well with reported values in literature (655–711 wt%) [12] , [27] , [32] , [35] Mechanism of magnetite iron ore concentrate morphology

.jpg)

Influence of Grinding and Classification Circuit on the

2019年12月17日 The depletion of high grade iron ore resources make it inevitable to utilize the existing low grade iron ores/ fines/ tailings with proper beneficiation to meet the present specification and demand2021年7月1日 Leading iron ore producers are already implementing SuperStack screening technology in innovative applications Vale SA, one of the world’s largest iron ore is installing SuperStacks for fine iron recovery at the Carajás mining complex to transform their tailings into positive cash flow with a by making a highvalue “green ore” product from what was previously Latest Advances in High Capacity, Fine Screening for the Iron Ore 2014年5月1日 Studies have documented the potential for the worldwide iron and steel industry to save energy by adopting commercially available energyefficiency technologies and measures [1], [4], [5]However, in view of the projected continuing increase in absolute steel production, future reductions (eg, by 2030 or 2050) in absolute energy use and CO 2 emissions will Alternative emerging ironmaking technologies for energy 2022年10月19日 iron ore is used to make steel Indeed, it has been argued that iron ore is “more inte gral to the global economy than any other commodity, except perhaps oil” Increasing iron ore demand, coupled with the depletion of highgrade hematite ores in the United States, after World War II led to development of lowergrade ironIron Ore Processing, General Springer

with increasing grade iron ore screening

Iron Ore Pellets Screening Solutions Metal 7 Iron Ore Pellets Screening Solutions The size distribution of iron ore pellets is among the most important quality parameters for the end users of those pellets, the steel mills The tighter the distribution is, the better the performance and energy efficient the steel making process will be2024年9月5日 Iron ore is an important raw material for manufacturing steel, while the grade of domestic iron ore is relatively low in China, thus it is difficult to concentrate(PDF) Experimental investigation on magnetic gravity 2024年3月16日 Iron ore is essential in steel making; however, highgrade ores have diminished, making lowgrade ores inevitable These lowgrade iron ores need further beneficiation to upgrade the iron content Currently, traditional physical and chemical methods are utilized and are not environmentally friendly Biobeneficiation techniques have emerged as a sustainable Towards a Sustainable and Enhanced Iron Ore Recovery: Bio 2014年4月3日 Fig 3 Types of processing ores The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore The wet process consists of multistage crushing followed by different Beneficiation of Iron Ores IspatGuru

Crushing characteristics and performance evaluation of iron ore

2023年12月1日 Due to the decreasing reserves of highgrade iron ore and secondary resources used for steelmaking, it has become an important research and development area to improve the grade of iron ore through crushing (Gul et al, 2014)The quality of iron ore crushing directly affects the performance of pellets and sinter, so as to influence the quality and performance of 2017年11月17日 Iron ore quality in India is deteriorating due to continual increase in consumption of good grade ores It is The low grade iron ore sample obtained from Eastern region of India was thoroughly hom ogenized and Table 2: Results of scrubbing , washing and wet screening of sample crushed t o 5 mmIron Ore Processing eprintsnmlindia2023年8月1日 Much of the remaining iron ore resources in Brazil consist of lowgrade itabirite ores Accordingly, a typical beneficiation circuit includes a fourstaged crushing/screening plant, followed by grinding in a closedcircuit ball mill, desliming in hydrocyclones and final ore mineral concentration via multistage reverse flotation and thickening of the final productTransforming iron ore processing – Simplifying the 2016年6月20日 AZ Guide to Screening Ore, Rock Aggregate A simple definition of a “screen” is a machine with surface(s) used to classify materials by size Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface”Ore, Rock Aggregate Screening (Complete Guide)

Process Optimization for Gangue Removal from LowGrade Iron Ore

2024年9月16日 This research aims to develop technology that can improve lowgrade iron ore containing a large amount of αFeOOH and gangue to the same level as the highgrade iron ores that are conventionally used The main goal is to optimize the alkaline hydrothermal treatment conditions for iron ore when using a flowtype reactor for constructing a development 2024年4月29日 Manganese is widely used in the iron and steel industry, batteries and other fields The amount of the manganese oxide ores existing in China coeval with iron and their manganesetoiron ratio is low A study was conducted on a synchronous reduction roastingmagnetic separation of a ferromanganese ore with high content of iron taken from South Africa Phase Transformation Law of Manganese and Iron Oxides in 2019年9月25日 Canadian iron concentrate (CIC) can elevate the ferrous grade and lower the contents of gangue components and harmful elements in the sinter To understand hightemperature characteristics of CIC and typical iron ore, the formation of the melt was calculated mainly through FactSage 72, and melt fluidity (MF) test for iron ore fines and penetration Oreblending optimization for Canadian iron concentrate during iron ore 2019年10月22日 There is a rise in demand for alternative lowgrade iron ores, due to the rapid depletion of highgrade natural iron ore resources and an increase in the need for steel usage in daily lifeA Novel and Green Metallurgical Technique of Highly Efficient Iron

.jpg)

Beneficiation of LowGrade Hematite Iron Ore Fines by

2024年2月8日 Beneficiation of lowgrade iron ore fines is considered to be a challenging task due to the smaller grain size and their complex association with the gangue matrix