Parts Of Granulator Mining Mill

.jpg)

Granulators WITTMANN Group

1 天前 Efficient medium besidethepress granulator for bulky parts from injection molding and/or blow molding applications with many optional features Screenless Granulators SMax Series of Besidethepress GranulatorsAuxiliary Equipment Granulators WITTMANN GroupAuxiliary Equipment2017年8月28日 ranular materials with controlled physical properties Granulation and related processes cover a wide range of techniques used to form agglomerates that range in size from THE SCIENCE AND ENGINEERING OF GRANULATION Granulators are essentially rotary grinders that are used to grind scrap parts and melt delivery systems (sprues and runners) into feedstock sized granules for reprocessing From: Handbook Granulators an overview ScienceDirect Topics

%3C1PGHL[2}HK_]YT.jpg)

Chapter 4 Drum Granulation Processes ScienceDirect

2007年1月1日 Granulation is the process of building up an optimumsized, nearly spherical product from fines, melts, or slurries The granulation is brought about when a bed of solid Roll Granulator Rigid materials can be sized With the Kurimoto granulator, you can adjust product sizes by changing the roll width and increasing the number of granulating stages Dryprocess Crushing and Sizing Machine Granulator2007年1月1日 In Fig 47, the discharged particles are fed to sieve and mill by gravity This principle requires a certain minimum height below the fluidizedbed unit The seeds are blown Chapter 9 Granulation equipment ScienceDirect2022年8月16日 1 Rotation of one or more shafts carrying staggered paddles in a fixed trough (pug mill) 2 Rotation of the whole device, such as drum or pan 3 Movement of particles by a third phase, as by blown air in a fluidbed granulatorGranulation equipment FerTech Inform

Understanding the Effect of Granulation and Milling

mill operating parameters (mill impeller speed, batch loading, mill run time and mill screen size) were kept constant The mill impeller speed was set at 3000 rpm, the batch loading was keptGranulators are employed in the coal industry where they size runofmine coal and remove tramp iron/debris at the same time Coal granulators have undergone various important Granulators TAKRAF TAKRAF2020年3月3日 thyssenkrupp Ring Hammer Mills – also known as Ring Granulators – are mainly used for crushing of coal in thermal power stations The material is crushed initially by impact Ring Hammer Mill RHM 1224 ThyssenKruppProcesses 2020, 8, 683 4 of 18 experiments Similarly, for all the experiments, the chopper speed and wet massing time in the granulator were kept constant at 6000 rpm and 3 min, respectivelyUnderstanding the Effect of Granulation and Milling

.jpg)

ring granulator type coal crusher makers in india Grinding Mill

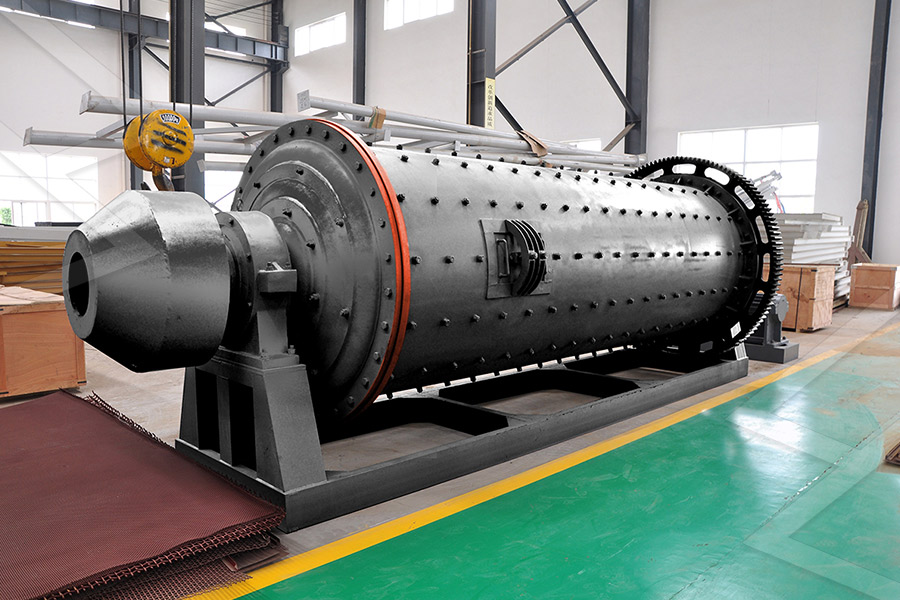

2021年7月14日 ring granulator type crusher ring granulator type crusher Granulator Manufacturers, High Quality Granulator pulverizer manufacturers Ball Mill Parts A ball mill consists of various components that work together to facilitate grinding operations The key parts include the following: Mining and Ore Processing: Ball mills are used for grinding ores and minerals, enabling the extraction of valuable metals They are widely employed in both wet and dry grinding processes for Ball Mill Grinding Machines: Working Principle, Types, Parts 2017年8月28日 reactions A granulator converts fine powdrs to granules via a series of physical rate processes Chemical reactor engineering is very well established We can apply many of the methologies from reaction engineering to approach granulator designT here are four natural scales of analysis for a granulator or reactor (figure 14): 1THE SCIENCE AND ENGINEERING OF GRANULATION 2024年3月1日 We want to discuss the distinctions between a granulator, vertical mill, and touch upon the turbo mill and their respective applications Granulators and wire choppers have long been synonymous, typically used together for four decades or so Over time, granulators have predominantly featured D2 steel blades in various blade configurations—staggered tooth, flat, The Difference Between Granulators and Vertical Mills ( Turbo Mills

.jpg)

UNDERSTANDING THE EFFECT OF GRANULATION AND

screen mills etc which can be classified on the basis of type of force applied to break the particles This study mainly focuses on conical screen mill granulator impeller speed and the amount of binder in the formulation are analyzed For the current work, Caffeine is chosen as the Active Pharmaceutical Ingredient The formulation used Spare Parts Granulator Die products found from trusted manufacturers suppliers Product List ; Supplier List; Secured Trading; Granulator Spare Parts High Productivity Dies forChina Spare Parts Granulator Die, Spare Parts Granulator Die 2 天之前 Working Principle Powder raw materials will be fed from the top equipment to join, the degassing, spiral compression and transmission to the two roll arc wall, two roll speed, reverse rotation, the material bite into the slot and forced compression, material by compressing area after the pressure gradually decreases, and its natural prolapse, surface tension and gravity into the Disc Fertilizer Granulation Rounding Machine Disc Granulator Mining 2021年4月19日 Published in MATERIA 2021;23:6366 The idea of minetomill optimization has been tested in various mines in last decades, resulting in higher mill throughput in many mines, but also Feasibility and necessity of mine to mill optimization in mining industry

HighShear Granulator: Operating Principles, Uses,

2024年5月20日 The chopper forms part of highshear granulator and is used to break down the wet lump to produce granules The chopper rotates at a speed of 1000 to 3000 rpm Powder densification and/or agglomeration are by the in cooperation of a granulation fluid into the powder with highpowerperunit mass, through rotating highshear forces 2024年10月15日 Zhejiang Tongli Heavy Machinery Manufacturing Co, Ltd 98 followers on LinkedIn Business Type: Manufacturer Verified Location: Zhejiang, China (Mainland) Verified Main Products: Vertical mill Zhejiang Tongli Heavy Machinery Manufacturing Rapid Mixing Granulator Fluid Bed Dryer / Processor Multi Attached Blender Tablet Coater Production Rapid Mixer Granulator Mark Maker Multi mill is used for highspeed Granulating, Change parts of SS perforated Screens also available at extra cost TECHNICAL SPECIFICATION OF MULTI MILLMULTI MILL Mark Maker Pharma2021年7月11日 mill should be inspected periodically for wear and preventative maintenance should be carried out on a systematic timetable Hosokawa’s Aftermarket Department stocks parts for Hosokawa’s Mikro Brand products and can usually ship parts within 24 hours To reduce the potential for unscheduled production interruptions,Air Classifying Mill hmicronpowder

.jpg)

China Granulator Small Gear Manufacturers Suppliers Factory

Granulator Small Gear Introduction: CIC is a more than 30 years manufacturer and reputed supplier of forged pinion and pinion shaft widely used in various machinery equipments in the fields of mining, metallurgical, chemical industry, construction, and so on CIC possesses professional design team, advanced equipment Send Inquiry2021年10月8日 Keeping wearcritical parts on hand While most plants benefit from keeping wearcritical parts on hand, this practice can be a lifeline for mining operations, which are often remotely located and can’t afford to hold off production waiting on a part Keeping wearcritical parts on hand can mean the difference between hours and weeks of downtimeThe fundamentals of rotary drum maintenance Canadian Mining At CM Shredders, we produce some of the most advanced tire granulators for reducing rubber shreds and chips into finely ground rubber pieces The CM Granulator features VForce knife technology to reduce rubber chip size into crumb rubber, while also separating fibrous material from within the rubber using a blower cyclone, a screening system, and filter bagsVForce Granulators Rubber Granulators CM Granulators1 天前 Efficient medium besidethepress granulator for bulky parts from injection molding and/or blow molding applications with many optional features +Screenless Granulators SMax Series of Besidethepress Granulators The economic choice with a compact design Low speed (27 rpm @ 50 Hz) screenless technology for the most efficient and cost Granulators WITTMANN Group

.jpg)

Grinding mills for mining and minerals processing Metso

Also the Premier™ mills and Select™ mills come ready to be easily integrated with our mill reline equipment and full mining portfolio providing a onestopshop for your minerals processing needs! Grinding mill spare parts Customized grinding mill parts including heads, shells, trunnions and liners, main bearings, gears and pinions, and Ring Granulator also known as Ring Hammer Mill, is a crusher that operates at relatively low speeds and has large reduction ratio It has multiple rows of Ring Hammers, which crush material by a combination of Impact and rolling compression LT Construction Mining Machinery is part of the highly successful LT Group, and engaged in Crushers – LT Construction Mining Machinery2020年3月3日 thyssenkrupp Ring Hammer Mills – also known as Ring Granulators – are mainly used for crushing of coal in thermal power stations The material is crushed initially by impact with ring hammers and in a further step by rolling compression between the ring hammers and screen cage plates before it is squeezed through the screen slotsRing Hammer Mill RHM 1429 ucpcdnthyssenkrupp2019年6月26日 GRANULATOR OPERATING MANUAL WO Series Machines Rotogran International Inc 4 Simpson Road Bolton, Ontario, L7E 1G9 CANADA Phone: (905)7380101 Fax: (905)7385750 Spare parts Page 38 12 Troubleshooting Pages 3940 13 Torque specifications Pages 4142 NTN Lubrication GRANULATOR OPERATING MANUAL Rotogran Inc

.jpg)

Advantages of GranulatorPart B bobshellzjkhx

2024年8月7日 We will continue to talk about the advantages of granulator/pellet mill machine in this news 1 Good liquidity and easy management Due to the good fluidity of the pelleted feeds, there is very little stickiness, and pelletized feeds are the most popular for farms that use automatic feeders to scale up dairy cows or poultry 22019年4月5日 RecoDust is believed to be an efficient way of processing steel mill dusts to produce reusable secondary raw material resources The rising costs of the steel production process and the increasing public attention towards environmental protection have caused steel plants worldwide to focus on emissionreduction processes and circular economy As a RecoDust—An Efficient Way of Processing Steel Mill Dusts2023年6月9日 Rotor Assembly Material Of SeFluid Bead Mill Series (optional) The rotor assembly is one of the key parts of an agitator bead mill It is also the final kinetic energy conversion device assembly Due to the high speed of rotation, the rotor assembly of an agitator bead mill must be highly resistant to fatigue, corrosion and abrasion In order toTechnical Specification SeFluidGranulator/pellet Mill Machine Spare Parts Driving Key , Find Complete Details about Granulator/pellet Mill Machine Spare Parts Driving Key,Szlh Series Granulator Ring Die,Pellet Mill Machine Spare Parts,Pelletizer Spare Parts Driving Key from Feed Processing Machines Supplier or ManufacturerLiyang Weifeng Equipment Co, LtdGranulator/pellet Mill Machine Spare Parts Driving Key Buy

.jpg)

Understanding the Parts of a Ball Mill Economy Ball Mill

2024年10月3日 The cylinder is the container that holds the ball mill grinding process together We size cylinders by their total volume when empty When selecting a cylinder, it’s important to pick a size that could potentially hold all of your grinding media, raw materials, and 25% of your total volume for processing space—what we consider the "working" area of the ball millSuperior granulation: The MG 150 wire granulator uses a blade mill to finely chop copper wire, resulting in unparalleled granulation quality This machine is capable of processing up to 550 pounds of cables per hour, producing nearly pure copper scrap with less than 02% plastic contamination Some parts of the MG 150 are sound proof to MG 150 Granulator for Copper Wire Solid Equipment Co1 4 inch crushed rock, appl; 1 9 rock crushers, rock crusher canyon rv park; 1 csmc china star crusher, weston apple and fruit crusher: amazon; 1 ton of sand price coal granulator crusher Mining Quarry Plant2022年5月18日 piece of Stokkermill equipment can be a part of an articulated and complex system that can maximize productivity by working in the best way Satisfying All Your Lifting Needs Low maintenance and high operating efficiency moleymagneticsinc 1 (844) MMAGNET (6624638) sales@moleymagneticsincGranulators SM Series Moley Magnetics

Sinogomine Industrial Technology Co,Ltd

2023年10月25日 This mini copper wire granulator machine is m [ protected] +86; 0086 Ball mill Rod mill Mobile Trommel Gold Wash Plant Gold Mining Wet Pan Mill Crushing Production Line Sanding Production Line Ore Production Line; Spare Parts; Case; Contact; Home > Products > Ore Beneficiation Machinery > GMS05 Mini 2024年8月13日 Nowadays, pellet mills and machines for making pellets play a key role in the industry In this article, we will discuss both industrial pellet mills and pellet mills , which are essential in the pellet production process Understanding the differences between these machines and their applications will allow you to choose the right machine for your specific Pellet mills: A Comprehensive Guide to Pellet Mills and Pellet 2024年9月20日 Understanding Mine to Mill is presented in five parts Part A – Setting the Scene provides some definitions of Mine to Mill (M2M) and the historical background A chronology of Mine to Mill developments is followed by brief descriptions of the very wide range of Mine to Mill applications which have been implemented over the last 15 yearsUNDErsTaNDINg MINE TO MILL 911 Metallurgist2021年2月2日 Sand Mill/Horizontal mill 1/64” to 1/8” 8001200 20003000 HSA Attritor 1mm 3mm 4001800 26002700 HQ Attritor 04mm 3mm 10001900 3000 sleeve the machine’s internal parts These materials include alumina, zirconia, silicon carbide, silicon nitride, tungsten carbide, rubber, polyurethane, and various plastics ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS

.jpg)

Solventless amorphization and pelletization using a high

2022年12月1日 IND crystals, ARG crystals, and SiO 2 were gently premixed at various weight ratios as described in Table 1, using a mortar and pestle, and the resulting mixture (303 g) and MCC spheres (3000 g) were placed in the high shear granulator and were treated in the same manner as the systems without ARG (Section 221), yielding the composite particles with ARG2024年8月7日 In this article, we will talk about the advantages of granulator/pellet mill machine 1 Pellet mill machine, such as wooden pellet machine, can avoid animals picky eatersFormulated feed has a variety of raw materials, nutrition, comprehensive, can prevent animals from the powder to choose their favorite, refused to intake of other ingredients Advantages of GranulatorPart A bobshellzjkhx2020年6月10日 Milling is an essential unit operation used for particle size reduction in solid oral dosage manufacturing The breakage of particles in a comil is due to the intense shear applied on the (PDF) Understanding the Effect of Granulation andOur cone crusher spare parts for AllisChalmers crushers and Svedala Hydrocone crushers are improved over OEM standards, for longer wear life and improved efficiency and throughput EXCEL™ premium trunnionsupported mill parts FT Series Mill EXCEL Mission Critical Support and Parts for Mining and Aggregates Industries English PDF AllisChalmers/Svedala Hydrocone Crusher parts FLSmidth

.jpg)

Integrated Copper Cable Granulator Gomine Recycling

That’s where copper wire granulators come in The working process of the copper wire granulator machine is roughly divided into 3 main parts: 1 Feeding: The granulator starts with scrap copper wire, almost all of which will be insulated When you’re dealing in high volume scrap wires, you can trust the granulator to do the work2018年4月12日 We will continue to talk about the advantages of granulator/pellet mill machine in this news 1 Good liquidity and easy management Due to the good fluidity of the pelleted feeds, there is very Advantages of GranulatorPart B LinkedIn2024年8月23日 Ball Mill, Cement Mill, Grinding Mill, Rotary Kiln, Cement Kiln, Lime Kiln SupplierHenan ZK Corp already has been growing up to a comprehensive company with strong ability of the whole system researching and designing on process technology and equipment manufacturing in the fields of building materials, mining, metallurgy, environmental protection etcBall Mill, Cement Mill, Grinding Mill, Rotary Kiln, Cement Kiln,