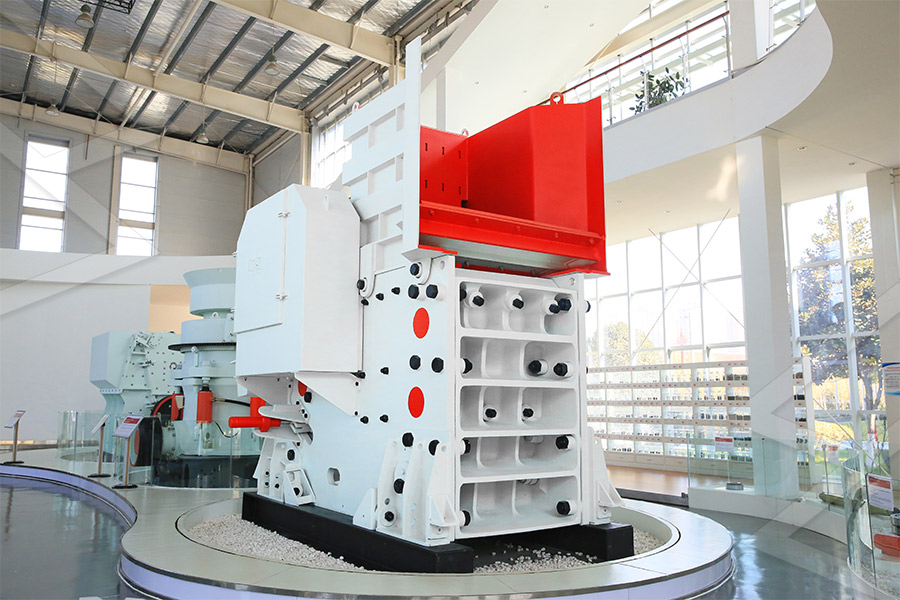

Impact Crusher Grecian

Impact Crusher ZHENGZHOU VANGUARD MACHINERY

Impact Crusher is another new breakthrough in the field of mine crushing equipment by Vanguard's technical engineersThe impact crusher are designed for crushing particle sizes 2024年3月1日 Derived a detailed kinematic model for dynamics of impact crusher swing mechanisms Analysed impact swing movements after particle impact Partitioned the analysis Impact crusher kinematics: The dynamics of an impact swing 2024年7月11日 Drawing inspiration from the crushing principle of the particles in the vertical shaft impact crusher, this study devised a rotary impact tester and established a cumulative The Crushing Distribution Morphology of a Single Particle 2024年10月27日 With integrated hybrid technology, the I4e delivers unbeatable results such as topquality end products and the lowest fuel consumption in the market with zero carbon emission due to plugin functionality! Due to the Greece welcomes Keestrack’s revolutionary I4e

.jpg)

Impact Crushers SolidsWiki

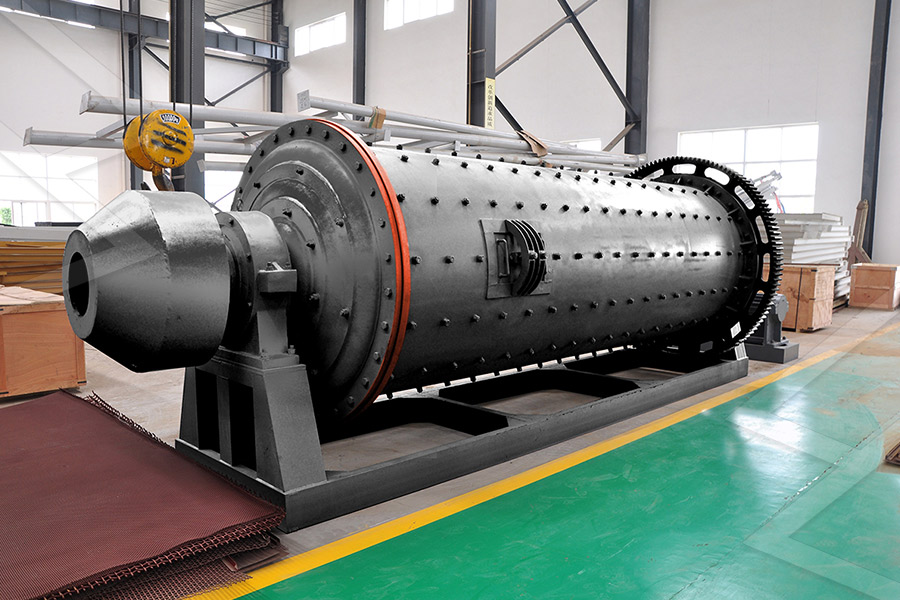

2022年7月7日 Impact crushing is a crushing method where comminution is by impact rather than by compression Sharp blows are applied at high speed to freefalling rock The moving parts are beaters, which transfer some of their 2024年8月14日 Impact crushers are a perfect fit for largescale operation, delivering high production rates and firstrate reduction ratios Lippmann impact crushers are made with Impact Rock Crushers: A Comprehensive Overview2024年8月27日 Impact crusher is a versatile and popular type of crushing equipment used across various industries They are a type of size reduction machine that uses high speed Impact CrusherSBM Industrial Technology Group2023年2月23日 In summary, the impact crusher working principle involves a highspeed rotor that rotates around a horizontal axis and strikes the material with a series of hammers The material is then shattered against the impact plates Understanding the Impact Crusher Working

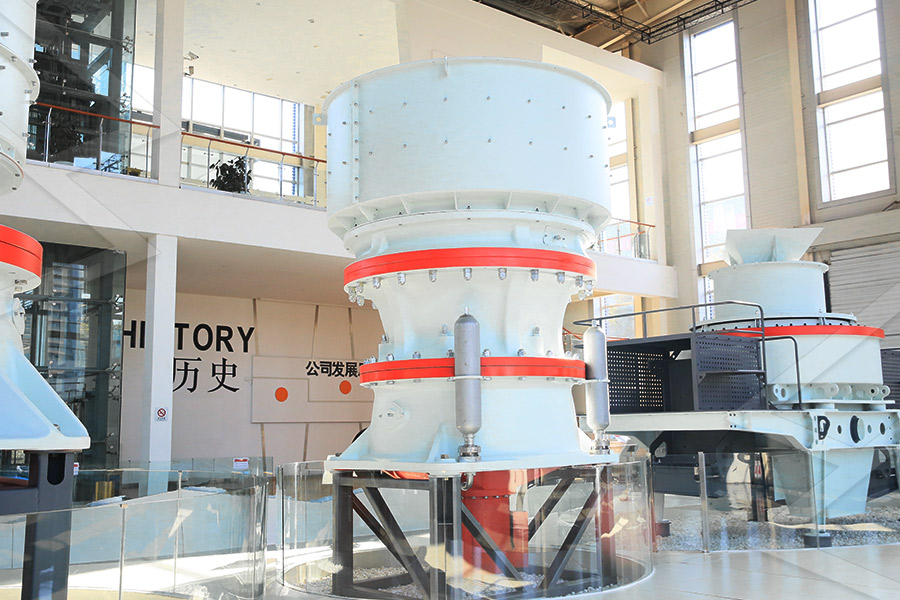

Impact Crusher an overview ScienceDirect Topics

Impact crushers (eg, hammer mills and impact mills) employ sharp blows applied at high speed to freefalling rocks where comminution is by impact rather than compression The moving Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes As the name suggests, an impact crusher accelerates the feed material to high Impact crushers highquality impactors MetsoOur mobile impact crushers are the result of combining the latest advancements in engineering technology and digitalization to provide a versatile and costeffective mobile crusher Everything that goes into the design of Sandvik Mobile Impact Crushers, QI Mobile Impact Operating the HTI Impact Crusher in the reverse direction This feature has a positive effect on the crushing performance and service life of the wear elements Switching the direction of operation has the effect of automatically regrinding the blow bars, which ensures a more uniform utilisation, and makes for a more consistent productTertiary Impact Crusher HTI HAZEMAG

Understanding the Impact Crusher Working

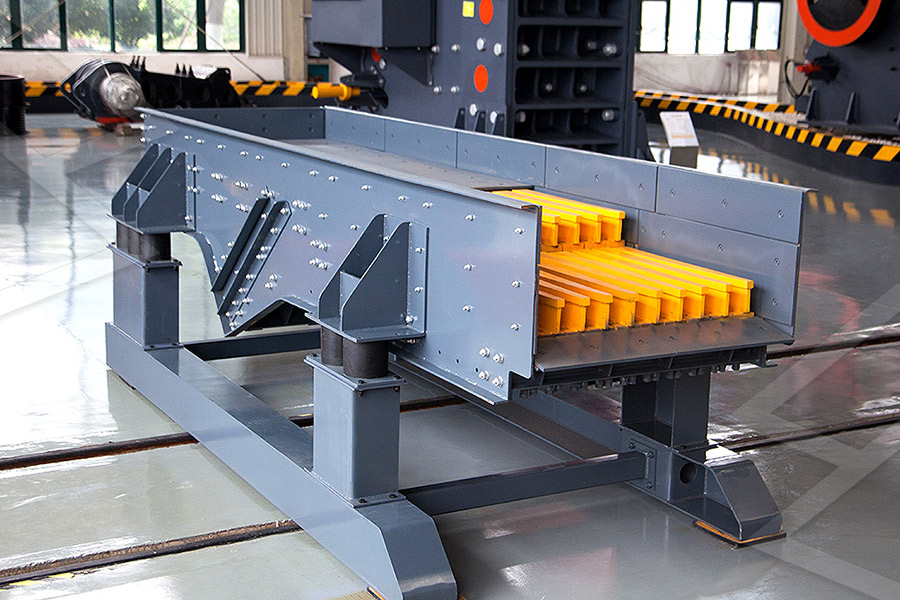

2023年2月23日 The impact crusher working principle involves a highspeed rotor that rotates around a horizontal axis The rotor is equipped with a series of hammers that strike the material as it enters the crushing chamber The 2024年10月29日 According to customer feedback, the impact crusher still runs well, which brings them huge benefits 2 180200 t/h limestone impact crusher in India Raw material: Limestone Final product: 0 – 44 mm Production demand: 180 – 120 t/h Feed size: ≦1,020 mm Configuration type: Jaw crusher+impact crusher+vibrating screenImpact Crusher with Various Models Fote Machinery2024年10月30日 The Powerscreen® Trakpactor 260SR is a compact impact crusher which has been designed to offer excellent reduction and high consistency of product yield With its compact design and ease of mobility, the Trakpactor 260SR is primarily suited to recycling, demolition, and mining applications A postscreen system and recirculating conveyor Impact Crusher Trakpactor 260SR Powerscreen2024年10月30日 The Powerscreen® Trakpactor 320 is a midsized horizontal impact crusher designed to offer operators and contractors both excellent reduction and high consistency of product shape for performance in quarry and recycling applications With track mobility, the impactor is capable of working in the most demanding environments and features a rapid Impact Crusher Trakpactor 320 Powerscreen

.jpg)

Impact Crushers Secondary McLanahan

The NGS Impact Crusher is extremely versatile The most common application involves taking primaryrun limestone from either a Jaw Crusher or impact breaker and reducing it into a construction grade aggregate However, with the optional third curtain assembly, it is possible to increase the amount2024年10月31日 The Powerscreen Trakpactor 290 Impact Crusher is a versatile and easy to use machine that can operate in the most demanding of applications such as construction and demolition, asphalt, concrete, and natural roTrakpactor 480SR Impact Crusher PowerscreenThe other type has a centrifugal crusher with vertical shaft, and it is called a vertical shaft impact crusher or VSI crusher Horizontal shaft impact crushers In conventional horizontal shaft impact crushers, the feed material is crushed by highly intensive impacts originating in the quick rotational movement of hammers or bars fixed to the Impact crushers highquality impactors MetsoAPF Series APF series is the most common small impact crusher for sale Philippines It is a twocavity impact crusher that can crush hard rock Thus, the impact stone crusher is widely applicable for coarse and medium crushing stagesWith two counterattack chambers, the APF series secondary impact crusher for sale Philippines has features of large processing capacity, Impact Crusher For Sale Philippines 37~400tph Capacity

Impact Crusher 911Metallurgist

2016年2月23日 Impact Crusher Advantages Before discussing the new economics of impact crusher usage, it might be well to briefly state the original, and still valid, advantages of the impact crusher in the production of friable aggregates Low original cost has always been the primary advantage of this equipment For a given application this first cost may 2024年8月15日 DOI: 1021062/mft2024072 Corpus ID: ; Design and simulation of secondary acceleration type rotor for vertical shaft impact crusher @article{Wu2024DesignAS, title={Design and simulation of secondary acceleration type rotor for vertical shaft impact crusher}, author={Canhui Wu and Limei Zhao and Cheng Zhang}, journal={Manufacturing Technology}, [PDF] Design and simulation of secondary Semantic ScholarAn impact crusher primarily relies on the force of impact to crush materials Its principle of working is strikingly different from jaw and cone crushers that utilize compression to break down materials In an impact crusher, when the materials enter the blow bar area, they get hit by the highspeed rotating hammer and are thrown to the impact What Is An Impact Crusher? Caldas Engineering and 2024年10月31日 The Powerscreen® Trakpactor 260SR is a compact impact crusher which has been designed to offer excellent reduction and high consistency of product yield With its compact design and ease of mobility, the Trakpactor 260SR is primarily suited to recycling, demolition, and mining applications A postscreen system and recirculating conveyor Impact Crusher Trakpactor 260SR Powerscreen

.jpg)

R 700 mobile impact crusher Rockster

2 天之前 The R700S mobile impact crusher is especially designed for limitedspace applications It is easily transported from one jobsite to another and has optimal combination of compactness and power Due to its ease of operation it makes your daytoday work cost effective more efficient compact transport size transport dimensions2024年3月4日 Impact Crusher Applications: Aggregate Production:Impact crushers are extensively used in aggregate production for crushing materials like limestone, granite, and basalt Their high reduction ratios make them effective in producing wellgraded and cubical aggregates for construction projectsImpact crusher application and spare parts introduction2024年9月10日 CI5X Impact Crusher adopts the heavyduty rotor with strong rotary inertia and high precision Meanwhile, it is equipped with highquality bearings, ensuring the precision and big holding capability of the rotor So, further, materials can be fully crushed The impact crusher 河南阿特朗智能科技 布袋收尘器Impact Crusher is another new breakthrough in the field of mine crushing equipment by Vanguard's technical engineersThe impact crusher are designed for crushing particle sizes less than 700mm and compression strength no more than 360MPa ComparedImpact Crusher ZHENGZHOU VANGUARD MACHINERY

.jpg)

How does an Impact Crusher work? RUBBLE MASTER

Impact crusher hammers, wear liners, and impact plates are consumables and need to be replaced frequently Wear items are chewed up in the crushing process and need to be monitored and changed frequently The higher the abrasion, hardness, and finescontent the faster the wear The rotor body holds hammers in place through a sliding system (see The mobile impact crusher MOBIREX MR 110i EVO2 can be universally deployed and produces firstclass final grain quality With a crusher inlet of 1100 mm and numerous technical highlights, a formidable production rate can be achieved MR 110i EVO2 Mobile impact crushersThe impact crusher is also called impact crusher It is mainly used in metallurgy, chemical industry, building materials, hydropower and other materials that often need to be relocated, especially for the operation of fluid stones in highways, railways, hydropower projects, etc Different types, scales and requirements of finished materials adopt multiple configurationsImpact Crusher Sanme2024年10月24日 What is an Impact Crusher? The Aggregate Industry (Cement, ReadyMix Concrete, Asphalt, Crushed Stone, Sand Gravel), wants to process rock, sand, and gravel into a salable product as efficiently and inexpensively as possible One such way to process these materials is sending gravel, rock, and sand through an Impact Crusher, which breaks up What is an Impact Crusher? Zenith Crusher

impact crusher Traduction française – Linguee

De très nombreux exemples de phrases traduites contenant "impact crusher" – Dictionnaire françaisanglais et moteur de recherche de traductions françaises2024年7月2日 The impact crusher is a kind of crushing machine which uses impact energy to crush materials When the machine works, driven by the motor, the rotor rotates at high speed When the material enters the action zone of the plate hammer, it impacts and crushes with the plate hammer on the rotor, and then is thrown to the impact device to crush China Impact Crusher factory and suppliers AscendThe 4244T features a heavyduty impact crusher unit with 39” (1,000mm) diameter rotor Click to Zoom in 4244T Left Side 4244T Right Side 4244T Hopper 4244T Fines Conveyor 4244T Main Conveyor Features Overview: Up to 120+ tons per hour production rate Suitable for secondary and tertiary applicationsScreen Machine 4244T Impact CrusherAs mentioned, an Impact Crusher is excellent for processing materials like asphalt and concrete into smaller, uniform pieces, thanks to their highspeed impact force They are particularly favored in recycling and demolition projects for their efficiency in reducing material size and producing fewer fines, which is crucial for the quality of What is an Impact Crusher and How Do They Work?

.jpg)

Impact crushers and mills with a horizontal shaft for

The impact crusher achieves very high crushing ratios in both the first and second stage This results in a wide range of salable, cubical final products The impact crusher can be repurposed into an impact mill for manufacturing fine grains by inserting a higher machine base and an additional grinding track This flexible solution allows you 2020年10月31日 The author in study [7] presents the results when using a centrifugal impact crusher of a new design with a hole in the loading neck to supply additional air at a speed of up to 48 ms 1 Studying the operational efficiency of the centrifugalimpact The thyssenkrupp Polysius Impact Crusher produces a single stage perfect feed material for a vertical roller mill thyssenkrupp Polysius Impact Crushers are installed as stationary, semimobile or mobile crushing plants with plant capacities of more then 4,000 t/h Contact thyssenkrupp Polysius GmbHImpact crusher thyssenkrupp Polysius Crushing Technologies23 小时之前 I54R Impact Crusher The I54R is built around a 1200mm (48″) x 1335mm (53″) fourbar impactor with a 1360mm (535″) x 950mm (37″) feed opening An independently vibrating doubledeck grizzly prescreen removes I54R Impact Crusher McCloskey International

.jpg)

Constructive and regime parameters of horizontal impact crusher

2019年12月19日 The developed horizontal impact crusher can be used instead of the widely used smallsized hammer mills, since, in comparison with them, its specific energy consumption is reduced to 50% Scheme Impact crusher blow bars, also known as hammers, are essential components in horizontal shaft impact crushers These thick alloy slabs are strategically inserted into the rotor, rapidly striking materials like asphalt, concrete, and natural stone Their primary function is to fracture materials, ensuring efficient size reductionBlow Bars Hammers for Impact Crusher Stellar HeavyNordberg® NP15™ impact crusher For excellent secondary and tertiary crushing performance Nordberg® NP20™ HSI crusher Superior secondary and tertiary crushing performance Parts and services Impact crusher parts Reliable impact crusher parts enable stable production without unexpected downtimeNordberg® NP Series™ impact crushers Metso2016 Sandvik, QI341, Impact Crushers, 2016 SANDVIK QU341 IMPACT CRUSHER, 7800 HRS, GOOD TRACKS, COMES WITH NEW PLATES FOR INSIDE CRUSHER AND TWO BLOW Construction Station Wayne, MI $134,900 Used 2012 TESAB Impact Crushers 623CT Impact Crushers For Sale Equipment Trader

.jpg)

Impact Crusher Trakpactor 550 Powerscreen

2024年10月30日 The Powerscreen® Trakpactor 550’s robust impact chamber features a twin apron, 4 bar rotor design, with hydraulic release aprons, hydraulic setting adjustment, hydraulic crusher overload is driven directly off the engine via clutch for optimum fuel economy2021年12月9日 One such way to process these materials is sending gravel, rock, and sand through an Impact Crusher, which breaks up the material by either striking it with a rapidly moving blow bar or by throwing it into a stationary anvil where it breaks upon impact Impact Crushers may be used as primary, secondary, or tertiary crushers depending on the What is an Impact Crusher? Zenith Crusher2024年10月30日 The Powerscreen Trakpactor 290 Impact Crusher is a versatile and easy to use machine that can operate in the most demanding of applications such as construction and demolition, asphalt, concrete, and natural ro Learn More about Trakpactor 290Impact Crusher Trakpactor 320SR Powerscreen2024年10月30日 The Finlay® I140 tracked impact crusher shapes the future through innovation This new generation impact crusher with redefined style and advanced technological design gives improved material flow and production capabilities in quarrying, mining, demolition and recycling applicationsI140 Impact Crusher Horizontal Impactor Tracked Crusher

.jpg)

What's the Difference: Impact Crusher vs Jaw Crusher JXSC

2024年2月20日 The impact crusher and jaw crusher are two popular machines, each known for its specific strengths and uses What sets them apart is how they crush materials, the type of stuff they handle, and the size of the products they produce This piece dives into what makes impact crushers and jaw crushers different, looking closely at their