verticalmillverticalmillverticalmill

Vertical millChina Pengfei Group Co,Ltd

Jiangsu Pengfei Group Co, Ltd has the great comprehensive ability to provide the best quality services on turnkey basis with the complete equipment、 the installation and the debugging for the new type dry process rotary kiln cement CONTACT US Beijing HENSON Engineering Technology Co Ltd : Tel: +86 +86 Vertical MillBeijing HENSON Engineering Technology Co Ltd2015年8月31日 With the market demand for efficient, highly flexible, and highcapacity plants for cement production, it was time to develop an innovative drive concept to cope with the Introducing the Vertical Roller Mill with Driven Rollers: An 3 天之前 A Versatile Lineup of Vertical Machining Centers (VMC) Whether you need a standard 3axis mill, a powerful 5axis machining center, or a small VMC for precision parts, there’s a Vertical Mills VMC Haas CNC Machines Haas Automation

Optimisation of the performance of a new vertical roller mill

2024年1月15日 The performance of two new Vertical Roller Mills (VRM) has been analysed using Computational Fluid Dynamics (CFD) The results show notable air ingress from the 3 天之前 Loesche Vertical Roller Mill (VRM) is a revolutionary mineral processing tool that operates without water, capable of grinding rocks and minerals up to 50mm in a single pass Loesche Vertical Roller Mill for efficient processingComplex applications require adaptable equipment – and that’s what our range of vertical mill technologies offers With multiple options for mill heads, spindle configurations, mill footprint, High rail vertical mills, gantries and profilers for precision 2023年11月14日 Vertical Mill Vertical Roller Mill is a new type of advanced pulverizing equipment featuring good performance and drying function Integrated with drying, pulverizing, and powder selection, Vertical Roller Mill is widely Vertical Mill Jiangsu Sailong Energy Saving

.jpg)

Vertical Mill Manufacturer,Vertical Mill

Vertical Mill After absorbing advantages from foreign superfine vertical mills and considering analysis of domestic clients' needs, Longyi makes targeted improvements on existing vertical mill's technology to develop a newtype 2022年8月24日 US California San Francisco Bay Area CA 94539 Arizona 1001 N Central, Suite 802 Phoenix, AZ 85004 China Guangzhou 56 Building 11, Changhua Creative ParkOverview of Types of Vertical Mills Fictiv2023年12月4日 Advantages of Vertical Boring Mills Vertical boring mills offer several advantages that make them a goto choice for many machining tasks Here are the main advantages of using a vertical boring mill: Handling Large Vertical Boring Mills: A Comprehensive Guide2021年1月1日 Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption, higher capacity, process simplifications and compactness but it is also very sensitive to vibrations and can deteriorate productivity if process optimization is varied slightly Hence to Review on vertical roller mill in cement industry its

Performance analysis of vertical stirred mill based on multi

2024年9月1日 The vertical stirred mill, as key grinding equipment, is widely used for the fine and ultrafine grinding of minerals, ceramic materials, chemical products, and others [1]The main structure of the vertical stirred mill includes a frame, a driving device, a cylinder, and a helical agitator, which drives the slurry and grinding media inside the vertical stirred mill to grind 2024年1月15日 An industrialscale vertical roller mill (M600) was analysed for air flow in this study This led to proposed modifications, which were implemented in a new mill design (M350) The M600 mill can operate under continuous mode and is used for fine grinding of materials The design of this mill is depicted in Fig 1 It comprises six vertical Optimisation of the performance of a new vertical roller mill 2024年4月28日 In the process of strip rolling, mill vibration induces vertical and horizontal displacements in the rolls and rolled parts, affecting the accuracy of the rolling analysis model Constant changes occurred in the rolling zone between the upper and lower working rolls due to mill vibration, resulting in slight vertical and horizontal displacements of the rolled pieces Coupled Vertical–Horizontal Vibration Characteristics of a2022年5月31日 The vertical roller mill (VRM) is commonly used for secondary and tertiary crushing processes in numerous industries In this study, the discrete element method (DEM) was employed to explore the crushing in an overflow VRM without air involved via the bondedparticle model (BPM) Particle crushing experiments on a laboratoryscale VRM were Analysis of vertical roller mill performance with changes in

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unit2024年11月1日 Vertical mills are celebrated for their versatility, handling a wide range of materials and operations from simple drilling to complex contouring, making them suitable for varied industries Ease of Operation and Maintenance These machines are generally easier to understand and operate compared to horizontal mills Maintenance is Horizontal vs Vertical Milling: An InDepth ComparisonJET Vertical Mills are precisionbuilt and designed to last When picking a 3Axis Vertical Milling Machine or any other type, JET has a large range of options that will suit your needs View as Grid List Items 115 of 408Vertical Mills 3Axis Vertical Milling Machines More for 2023年10月3日 Base Frame: The support base of the vertical mill is generally four peripheral support pedestal and a central support base, and the support base and the installation foundation are connected and fixed by anchor bolts All the cement vertical roller mills of Tongli will be preassembled and leveling calibrated before leaving the factory to What is a vertical roller mill (VRM)? A Comprehensive Guide

)D`ERF`389RMI4.jpg)

Numerical Investigation of Vertical Roller Mill Operation

2023年12月4日 A vertical roller mill (VRM) is a grinding equipment used for the size reduction of minerals, cement, and ceramics The capacity of the VRM depends not only on the grinding material properties but also on the operational parameters of the VRM This study investigatedVertimillreg; is globally recognized as an energy efficient grinding machine Through a low total cost of ownership, they bring substantial improvement to the profitability of concentrators During the years, Vertimillreg; technology has Vertical mill Vertimill® 7000 Metso 2023年7月4日 The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement It can be divided into vertical roller mill, horizontal cylinderrollermill,highpressurerollermill,Raymond mill, and column mill Vertical Roller MillRoller Mill SpringerVertiSense™ is a digital solution for Vertimill ® stirred milling technology It is a novel system designed to enhance the grinding process in Vertimill ® that enables the wear monitoring of screw liners in real time and maximize operational efficiency through intuitive software and analytics Key benefits: Easy to install, maintain and use; Optimizes efficiency by ensuring wear parts are Vertimill® Metso

.jpg)

UBE Vertical Mill UBE Machinery Corporation, Ltd

2024年1月31日 The vertical mill allows the installation area to be decreased, leading to a reduction of construction cost 3 Easy operation Material feed, grinding force, air volume and separator feed can be adjusted through a remote control system, which makes the operation easier 4 Simple maintenance2021年8月20日 A vertical mill is characterized by a vertically oriented spindle that holds and rotates the cutting tool against the workpiece In a vertical milling machine, the part is fixed on the table and the table is moved crosswise by the saddle movement and maybe feed in the longitudinal, cross and vertical directions Vertical Mill vs Horizontal Mill Difference Between Junying2024年10月13日 Vertical mills are essential equipment in many industrial processes, and proper maintenance and care are crucial to ensure their reliable operation and longevity Regular inspection is a fundamental aspect of vertical mill maintenance This includes checking the condition of the grinding rollers, the grinding table, and the liners for signs of Key points for maintenance and care of vertical mills2024年4月1日 Figure 37 Size analysis for a repeat experiment performed in a vertical mill shown as a function of grinding time for a single 595 +420μm feed size 71 Figure 38 Vertical mill geometry (left) and RockyDEM simulation of the vertical millPREDICTING THE PRODUCT PARTICLE SIZE

.jpg)

CNC Knee Type Vertical Milling Machines Sharp Industries Inc

The AcuRite Millpwr G2 control and the FAGOR 8055i control are available for the series of vertical mills Different sizes of mills with R8 spindle, 3 HP motor to #40 taper, 5 HP features are available The 2 axes control the table and saddle (X, Y axis) movements, providing precise control over your machining operations2022年4月4日 2 VERTICAL ROLLER MILLS INTERNATIONAL CEMENT REVIEW SEPTEMBER 2021 played by the mill foundation, which has been optimised to reduce vibrations2 Built to last The mill foundation, ie, the basic block with its four concrete pylons, is responsible for the smooth running of the mill The roller units and mill housing are notVERTICAL ROLLER MILLS A holistic VRM approach2016年9月1日 Modern cement plants trend for the usage of vertical mill in cement grinding because of its many advantages of lower energy requirements, higher feed rates, simple layout (drying, grinding Operational parameters affecting the vertical roller mill 2023年12月22日 The vibration problem is the key factor that restricts the stabilization and working performance of the precision cold rolling mill As the sheet thickness becomes thinner and the rolling speed increases, the abnormal vibration that occurs in the cold rolling mill becomes more serious and frequent [1, 2]Variations in system parameters can induce changes in the Vertical nonlinear vibration analysis of cold rolling mill

.jpg)

Cement mills and raw mills for high throughput rates Gebr

The highest wear occurs on the wear parts of the grinding elements as is the case with any type of vertical mill Therefore, ease of replacement and regeneration is a major feature of the mill The MVR mill has a modern hydraulic system used in operation and for maintenance alike With this new type of roller suspension, the rollers can be 3 天之前 The completely redesigned Super Mini Mill is enhanced with allnew FEAoptimized base and column castings, larger travels, a sidemount tool changer, and fast spindle speeds and rapids for increased production outputAn allnew Yaxis washdown nozzle improves chip flow inside the machine, and a new 45gallon (170liter) external coolant tank simplifies maintenanceSuper Mini Mill 40Taper Mill Vertical Mills – Haas CNC 2017年8月12日 1 A background to drives of vertical roller mills The drive of a vertical roller mill – essentially the mill gearbox – has to fulfill two tasks: The first is to reduce the speed of the electric motor to the selected mill speed and to transmit the torque created by DRIVE SELECTION FOR LARGE LOESCHE VERTICAL The vertical mill model 1250II is a 5 horsepower (5HP), 40 taper spindle machine, with square (box) ways Our mill machine model WM3VS has a rounded ram and column The knee mill models 1050, 1050II, and 1250II have heavy duty square rams and columns with substantial knees and saddles These mill machines all maintain “Meehanite” castings Conventional Knee Mill Machines / Vertical Knee Mills

.jpg)

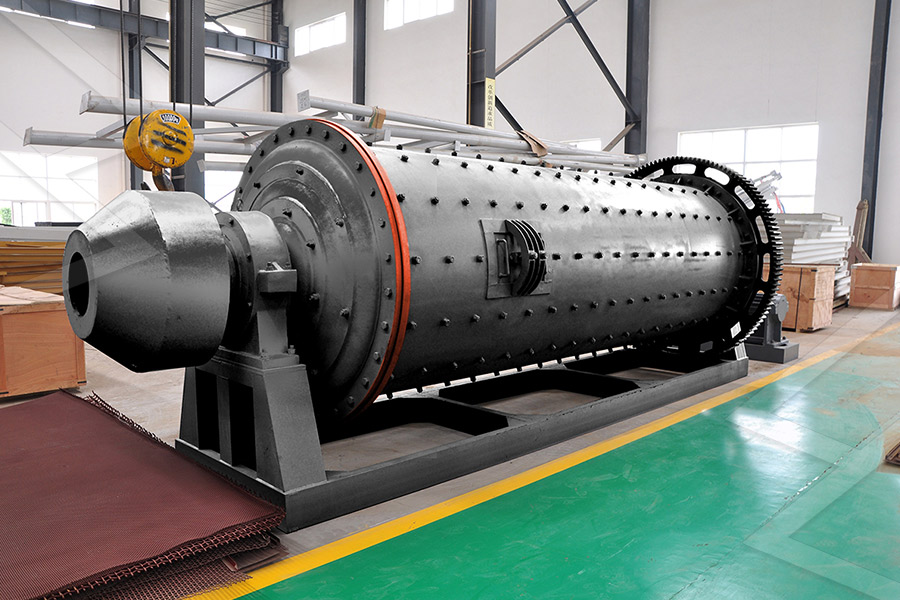

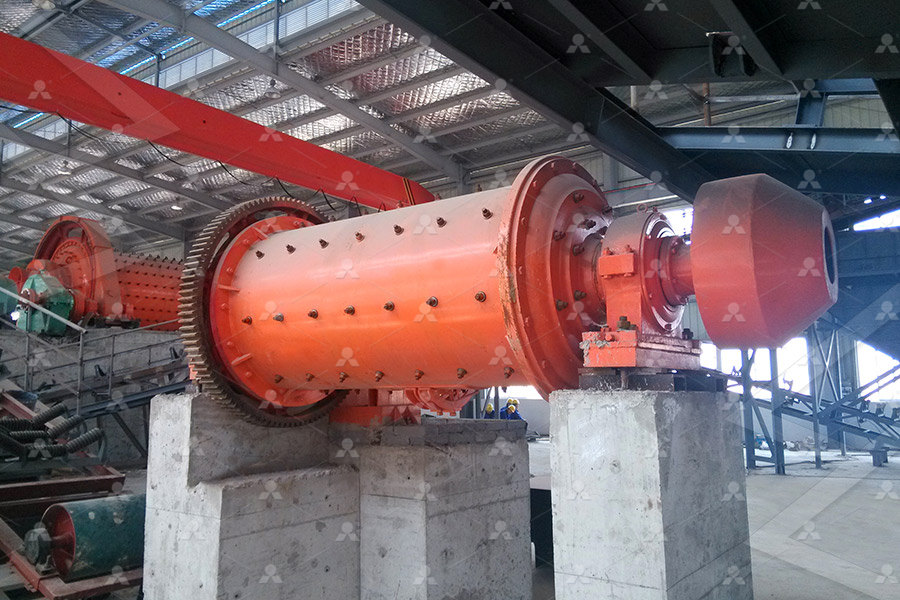

A Comparative Analysis: Vertical Roller Mill vs Ball Mill

2023年9月21日 Vertical Roller Mill: vertical roller mill is also known for their high grinding efficiency The compression and shearing forces exerted by the rollers on the material provide effective grinding action Particle Size Control Ball Mill: ball mill offers relatively limited control over the final particle size distribution The size reduction is 2024年7月1日 Find the Right CNC Vertical Milling Machine for Your Production Needs Experience the Absolute Machine Tools difference, where cuttingedge CNC vertical milling machines and an unwavering commitment to your success come together to advance your manufacturing capabilities Complete the form below to contact us today or call (800) 8527825CNC Vertical Milling Machine CNC Vertical Mill Absolute The Vertical Hammer Mill is classified under our comprehensive Grain Processing Machinery rangeIn China, sourcing reliable suppliers of grain processing machinery can be achieved through online B2B platforms, industry exhibitions, and verified supplier directories Prioritize evaluating supplier abilities, testing product quality, and Vertical Hammer Mill MadeinChina2015年8月31日 With the market demand for efficient, highly flexible, and highcapacity plants for cement production, it was time to develop an innovative drive concept to cope with the demand: the world's first vertical roller mill (VRM) with driven rollers With this concept, it is the rollers of the VRM that are driven, notas is usually the casethe grinding table With the rollerdriven Introducing the Vertical Roller Mill with Driven Rollers: An

.jpg)

An investigation of performance characteristics

2020年8月12日 Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining 2024年11月1日 VF1 Haas CNC Vertical Mill with 20" x 16" x 20" travels Discover Haas CNC machine toolsVF1 VF Series Small 40Taper Mill Vertical Mills – Haas The Vertical Mill is a premium choice in the Grain Processing Machinery categoryIn China, sourcing reliable suppliers of grain processing machinery can be achieved through online B2B platforms, industry exhibitions, and verified supplier directories Prioritize evaluating supplier abilities, testing product quality, and arranging onsite Vertical Mill MadeinChina2024年1月1日 About Chainsaw Milling Chainsaw milling is a method of sawing that uses a chainsaw and a milling attachmentIt’s a viable alternative to large, expensive machinery Different Types of Chainsaw Mills There are primarily two chainsaw mill types: Alaskan Mill – portable and attaches to the saw’s bar Vertical Mill – handles vertical cuts, slicing stumps and Chainsaw Mill Guide: Your Path to Expert Milling

.jpg)

EVALUASI KINERJA VERTICAL ROLLER MILL (Cement Mill)

2024年3月19日 Roller vertical mill berjumlah enam buah dengan bentuk S dan M I Srapper Pada vertical mill terdapat empat buah scrapper yang terbuat dari plat tebal dan berbentuk segitiga siku – siku2019年10月11日 From humble beginnings 113 years ago, family owned business Loesche a has taken the vertical roller mill (VRM) to the forefront of modern day milling Consequently, efficiency in energy used can be as much as 40% – 45% less than a wet ball mill circuit – noticed with all power going into the comminution of the ore Vertical roller mills: The new leader in grinding technologyMilling Machines Vertical Mills for sale listings We have 365 listings for Vertical Mills listed below Find items by using the following search options You can also click on the column heading to sort through the listings For more information on an item, contact the seller directlyVertical Mills for sale listings MachineToolsThe OK™ Mill is offered in a complete size range, including 3, 4 and 6roller mills, and the largest vertical roller mill size available with installed power over 11 500 kilowatts This ensures the ability to meet all possible capacity requirements in a single vertical roller mill solutionOK™ Raw and Cement Mill FLSmidth Cement

Cement mills and raw mills for small to medium throughput

MVR vertical mill with conventional drive: economical solution for small to medium output rates For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is the right choice This mill type is by the way the core piece of our modular Vertical ball mill is a mill in which the barrel is vertically fixed and the grinding medium is driven by the grinding shaft to grind the material The vertical ball mill integrates the dispersion and grinding of materials, and the grinding medium has a strong impact force in the barrel It is suitable for materials with high viscosity and Vertical Ball Mill